WAREHOUSE ORDER CREATION RULE (WOCR)

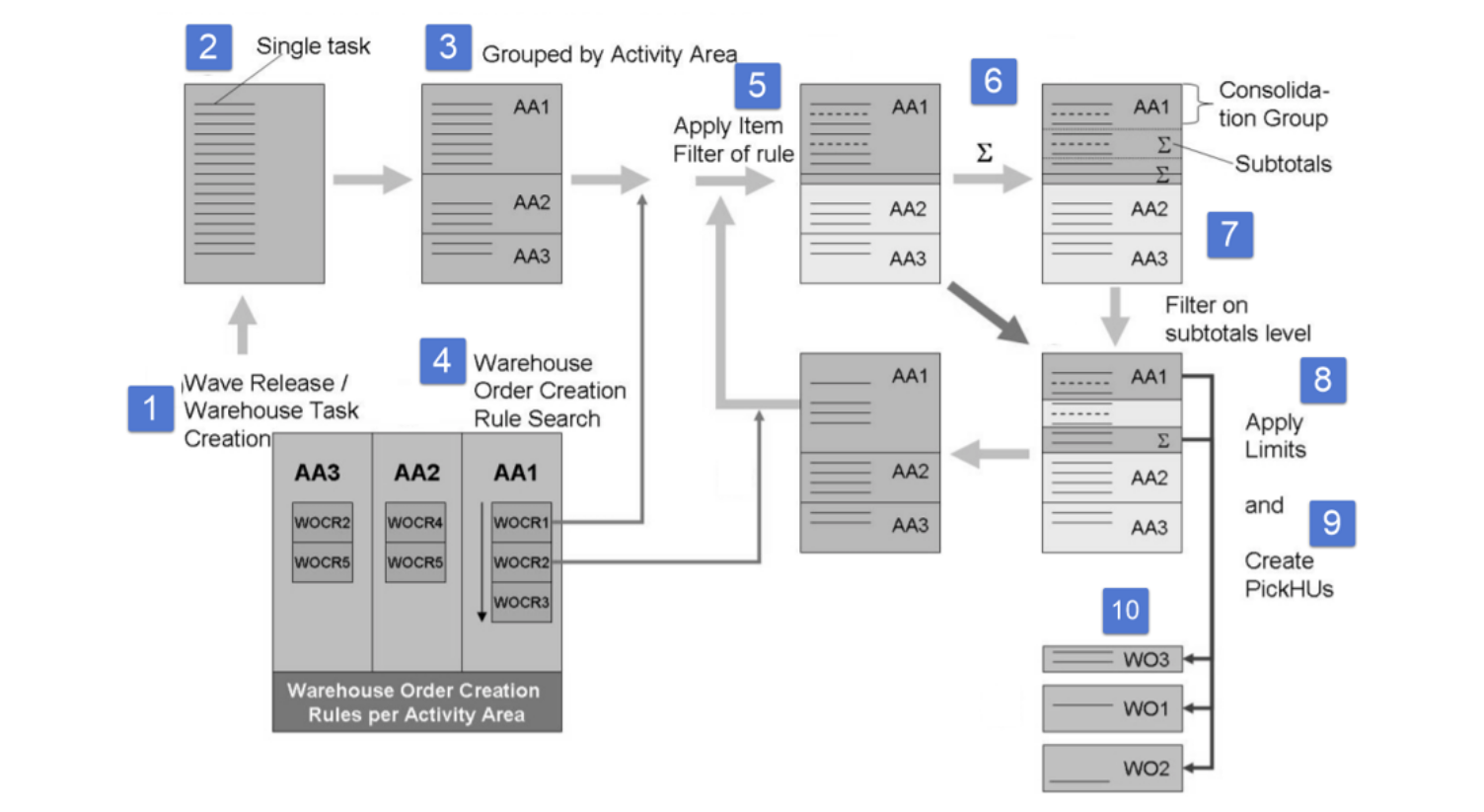

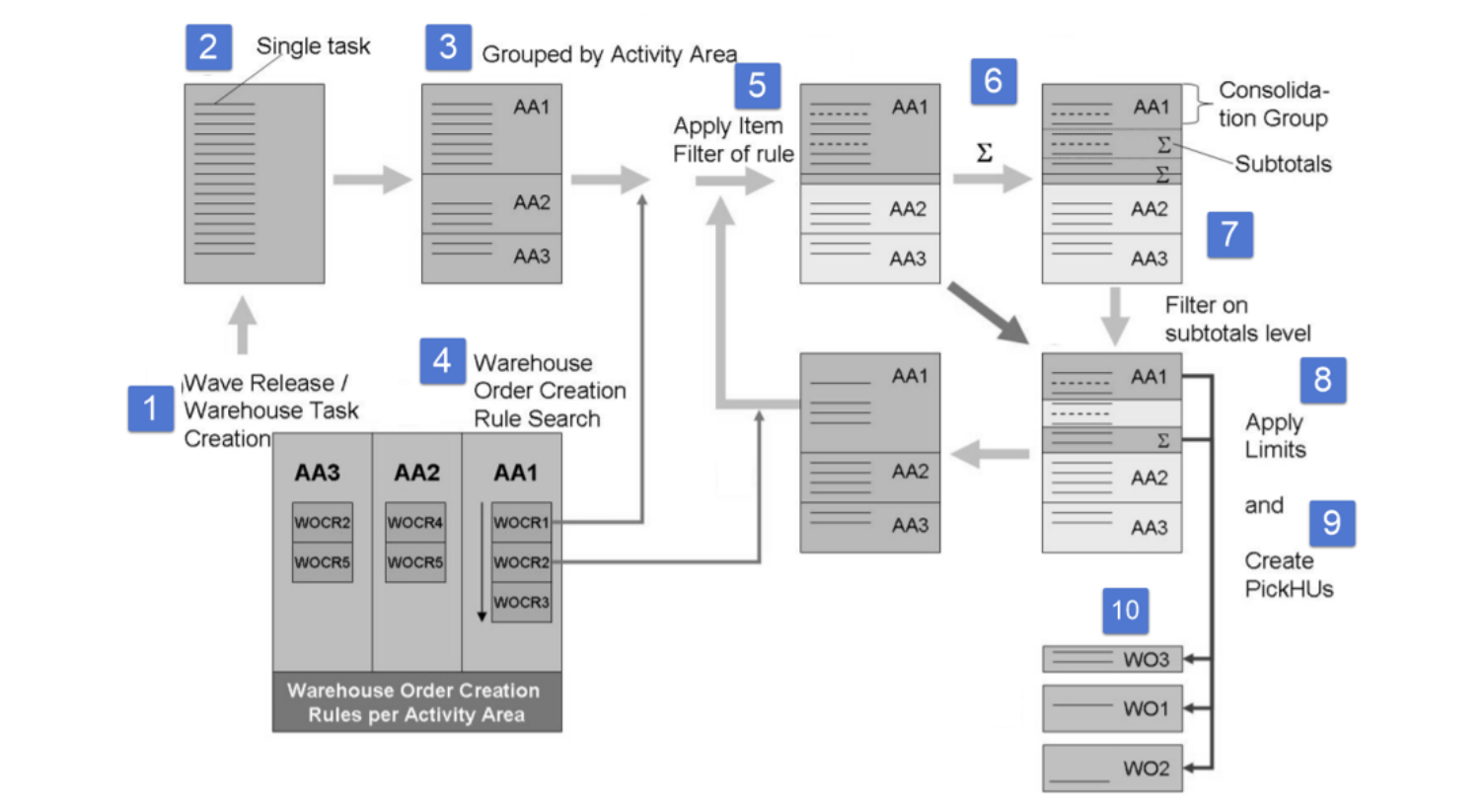

Copyright for the above image belongs to SAP Press.

Copyright for the above image belongs to SAP Press.

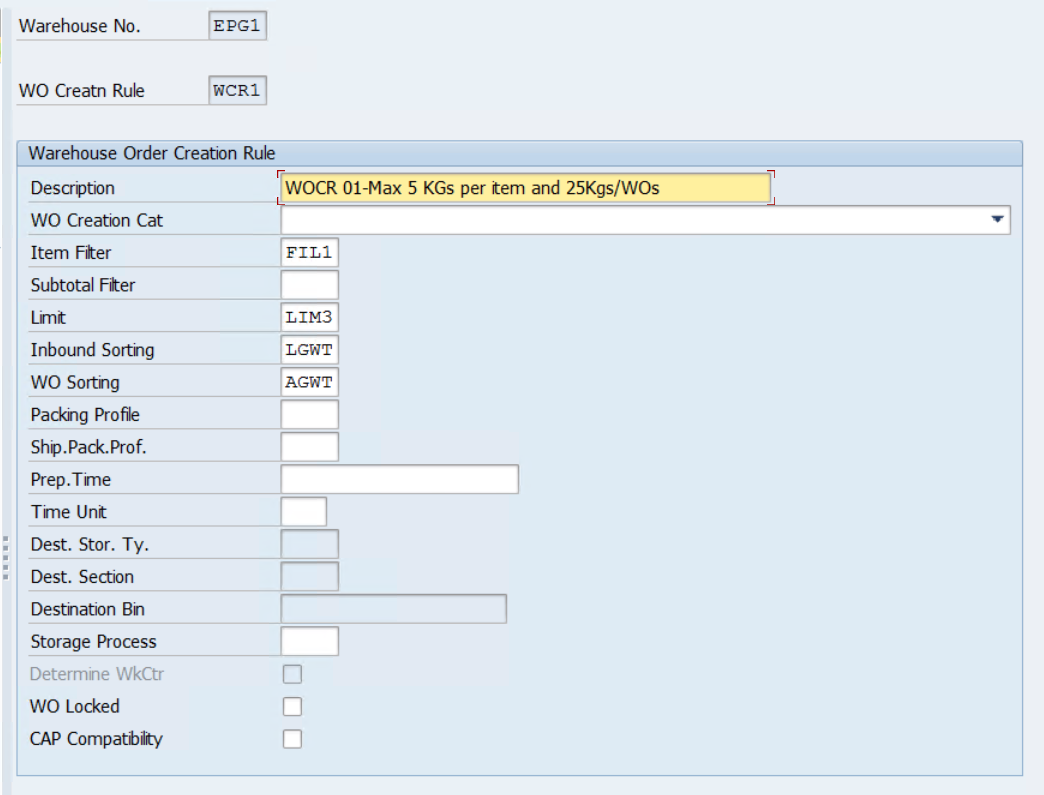

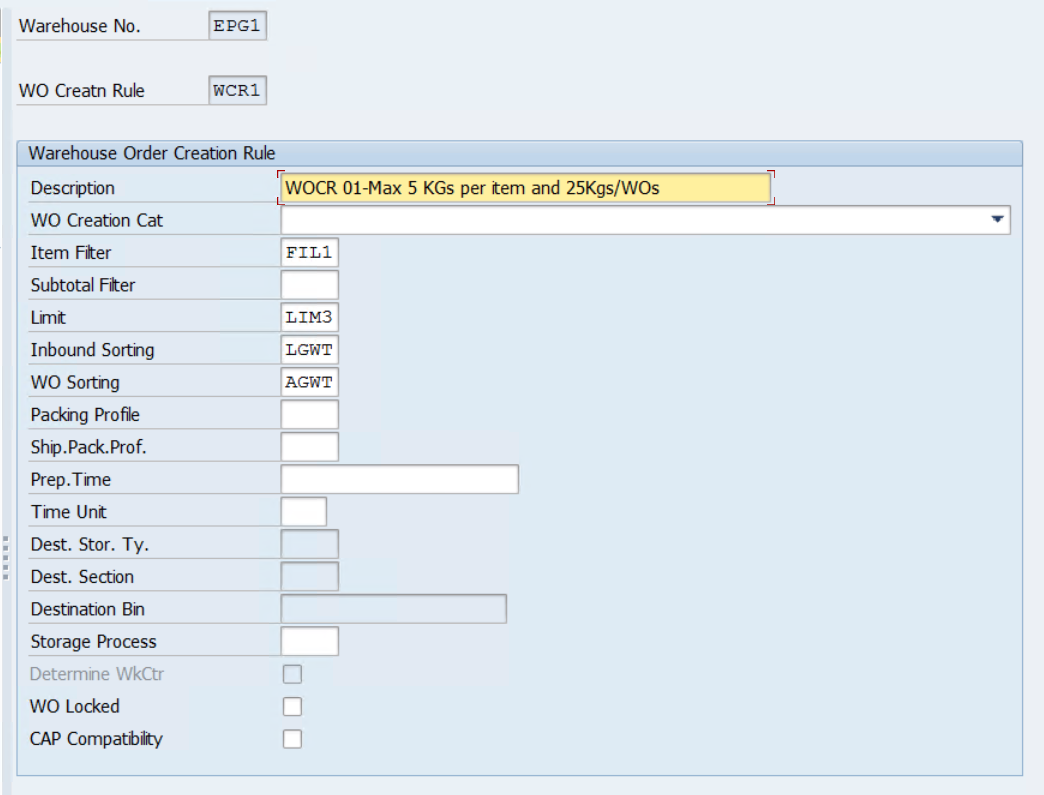

As the name suggests, it is a Rule to bundle various Warehouse tasks into a Warehouse Order.

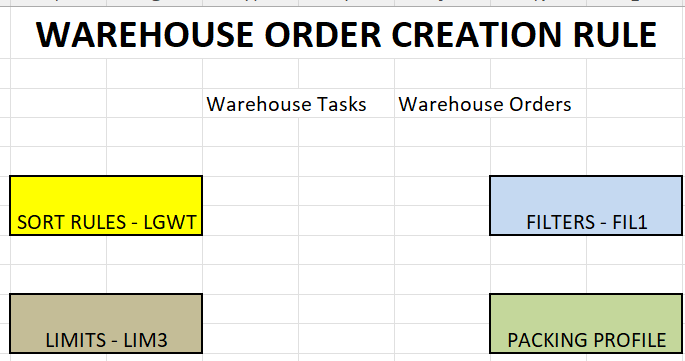

This Rule has some criterions listed down below:

SORT RULES LGWT – It has Sort Field WEIGHT (ascending Order)

By default, if the checkbox is not ticked – it means ascending.

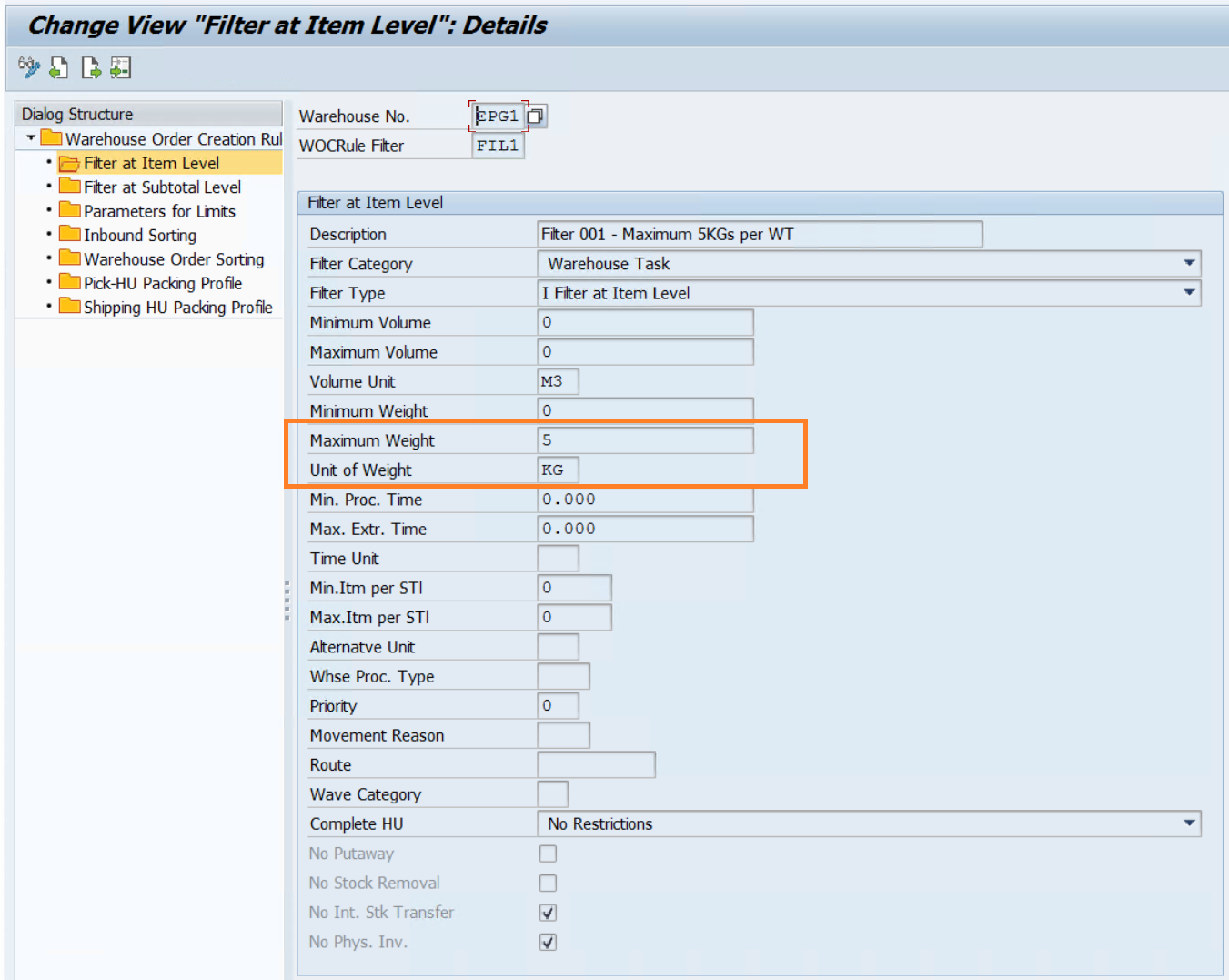

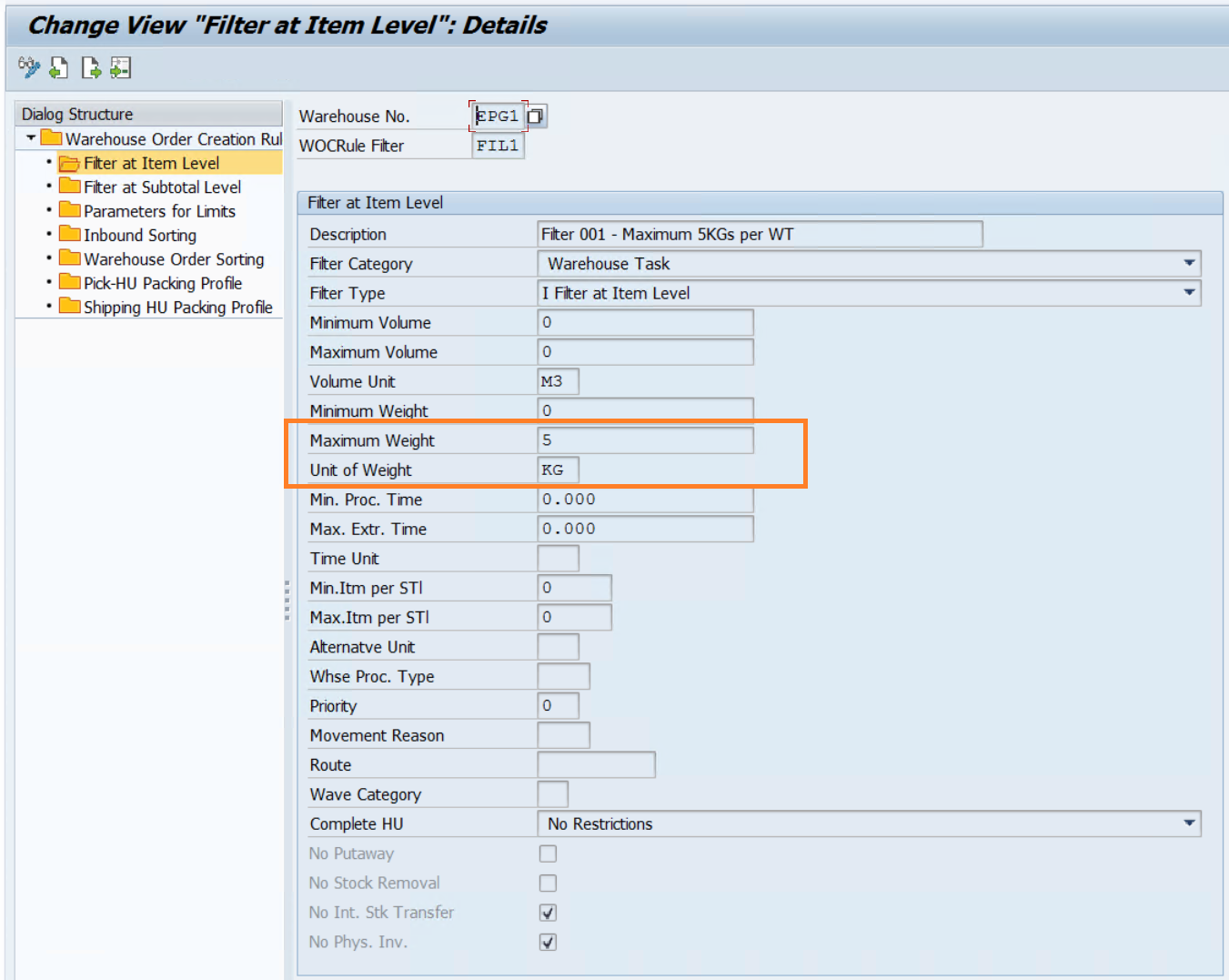

ITEM FILTER FIL1 – It has restrictions of filtering WTs less than or equal to 5KGs

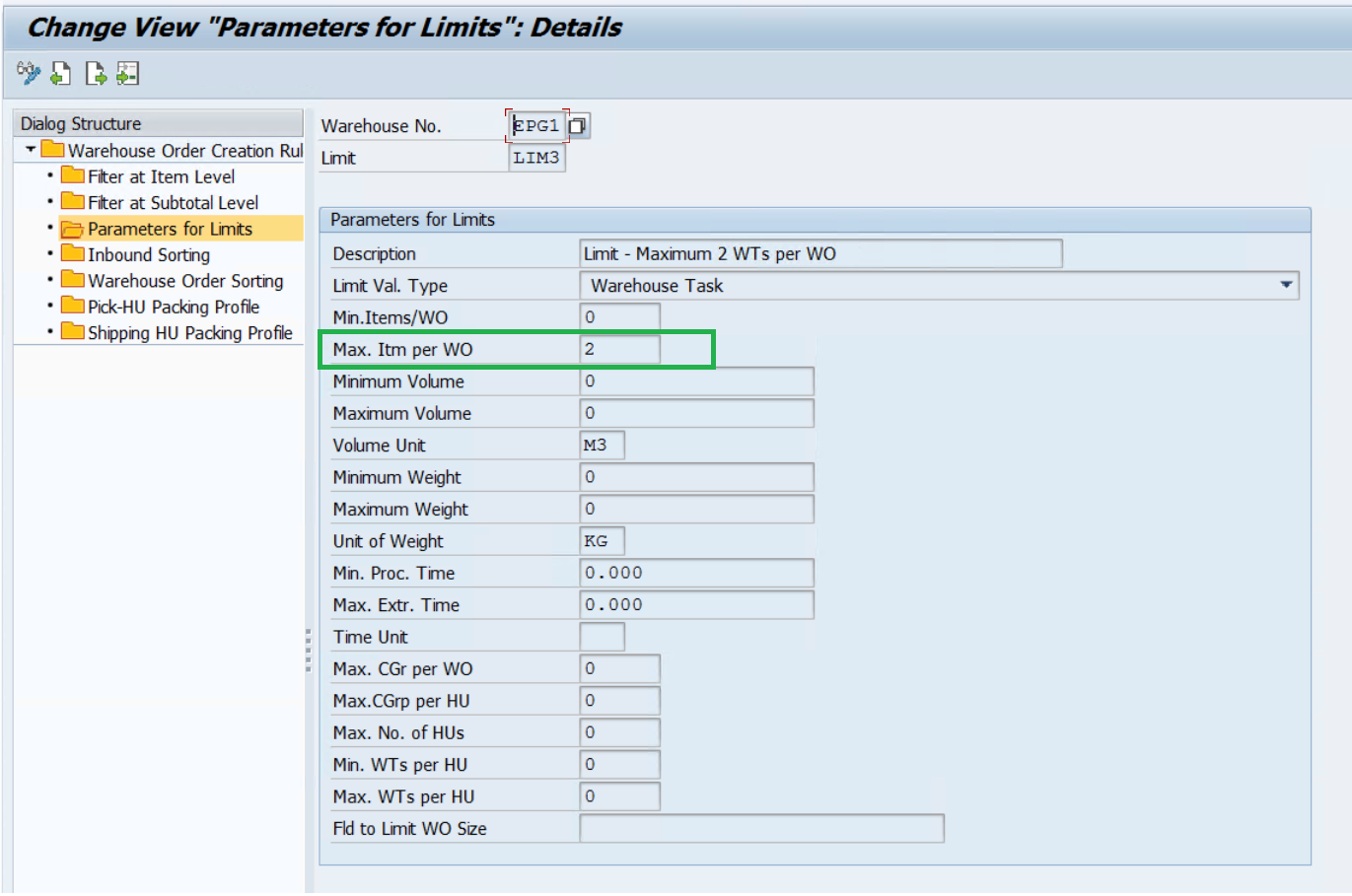

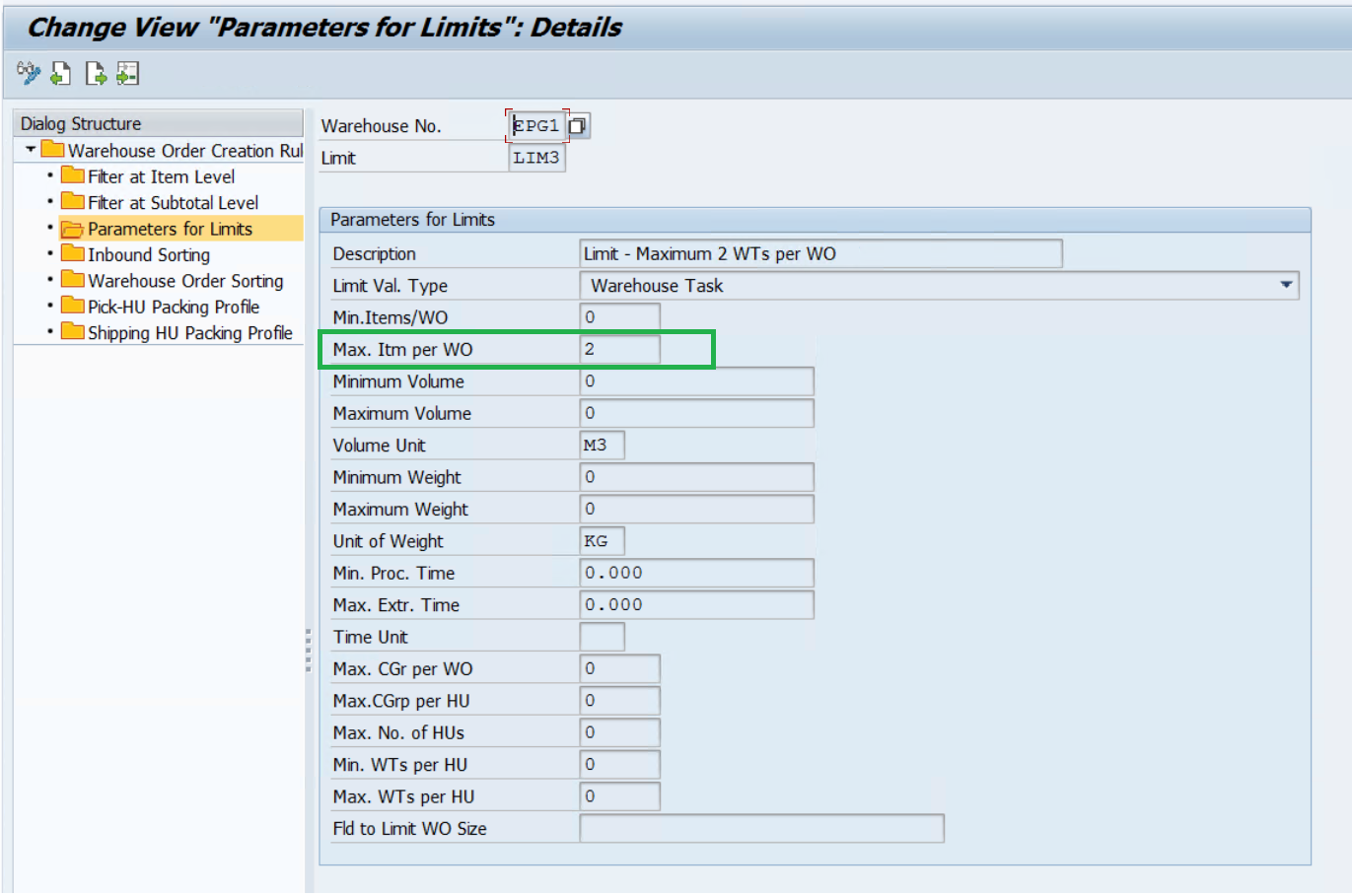

LIMIT LIM3 – It will limit the total number of WTs per WO, in our case the same can be less than or equal to 2 WTs per WO.

SAP EWM standard gives 3 WOCRs:

- DEF (Default) – Uses SORT RULE ‘PIPA’ (Field is PATHSEQ in ascending manner)

- UNDE (Undefined) – Uses SORT RULE ‘PIPA’ (Field is PATHSEQ in ascending manner)

- MFS (Material Flow System) – Limits a maximum of one WT per WO, makes sense since these WOs would be operated by machines which are capable of only executing one task at one point of time.

WOCR Determination:

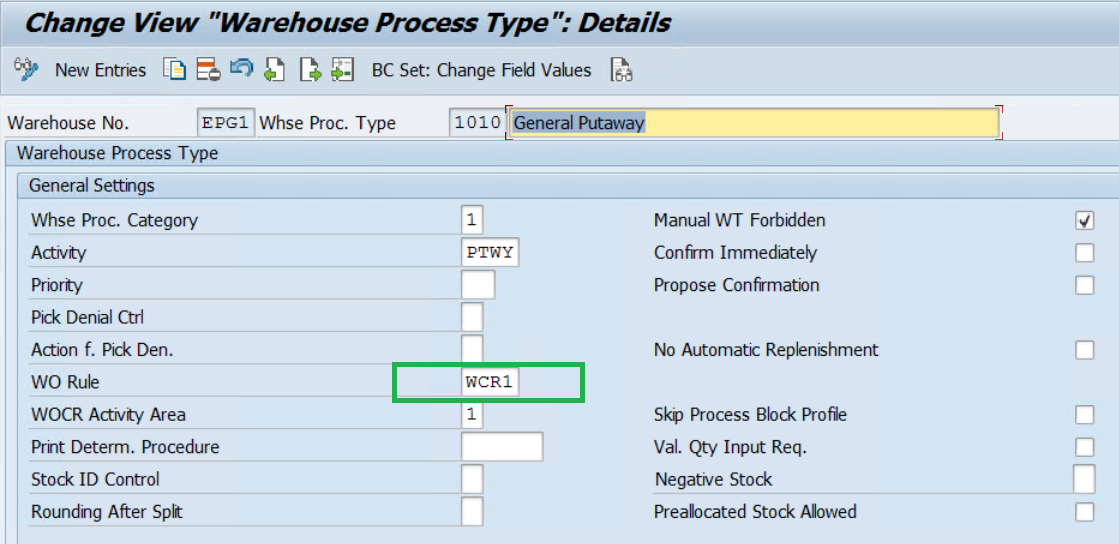

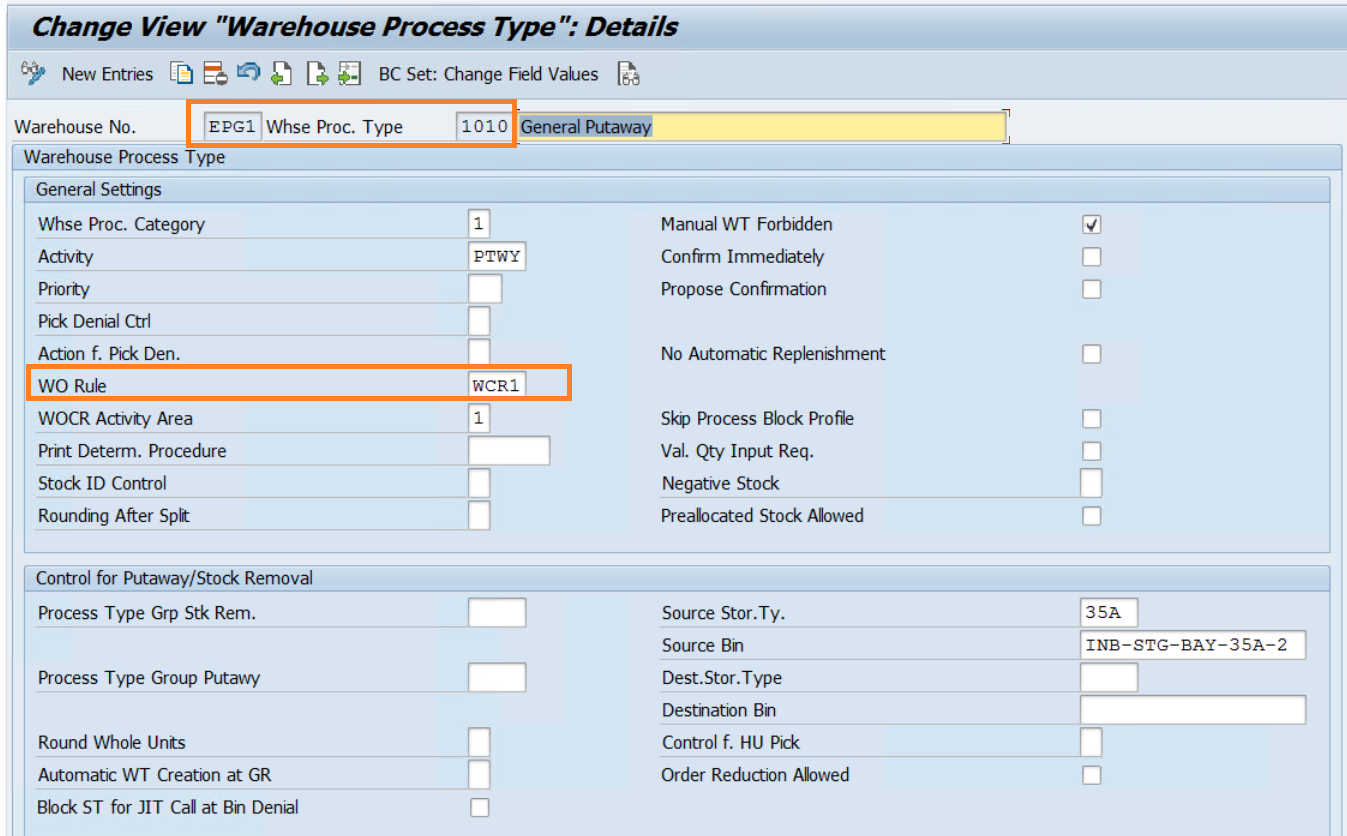

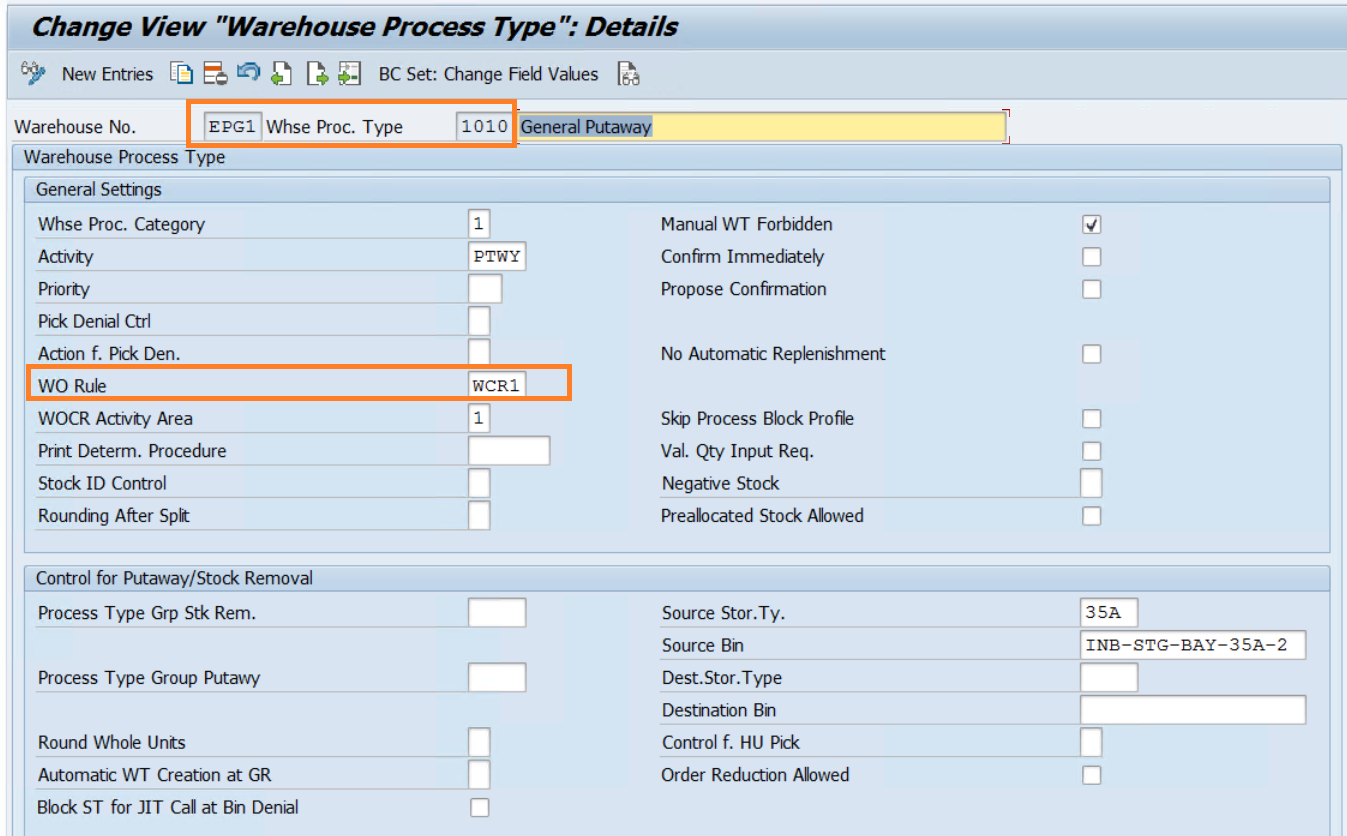

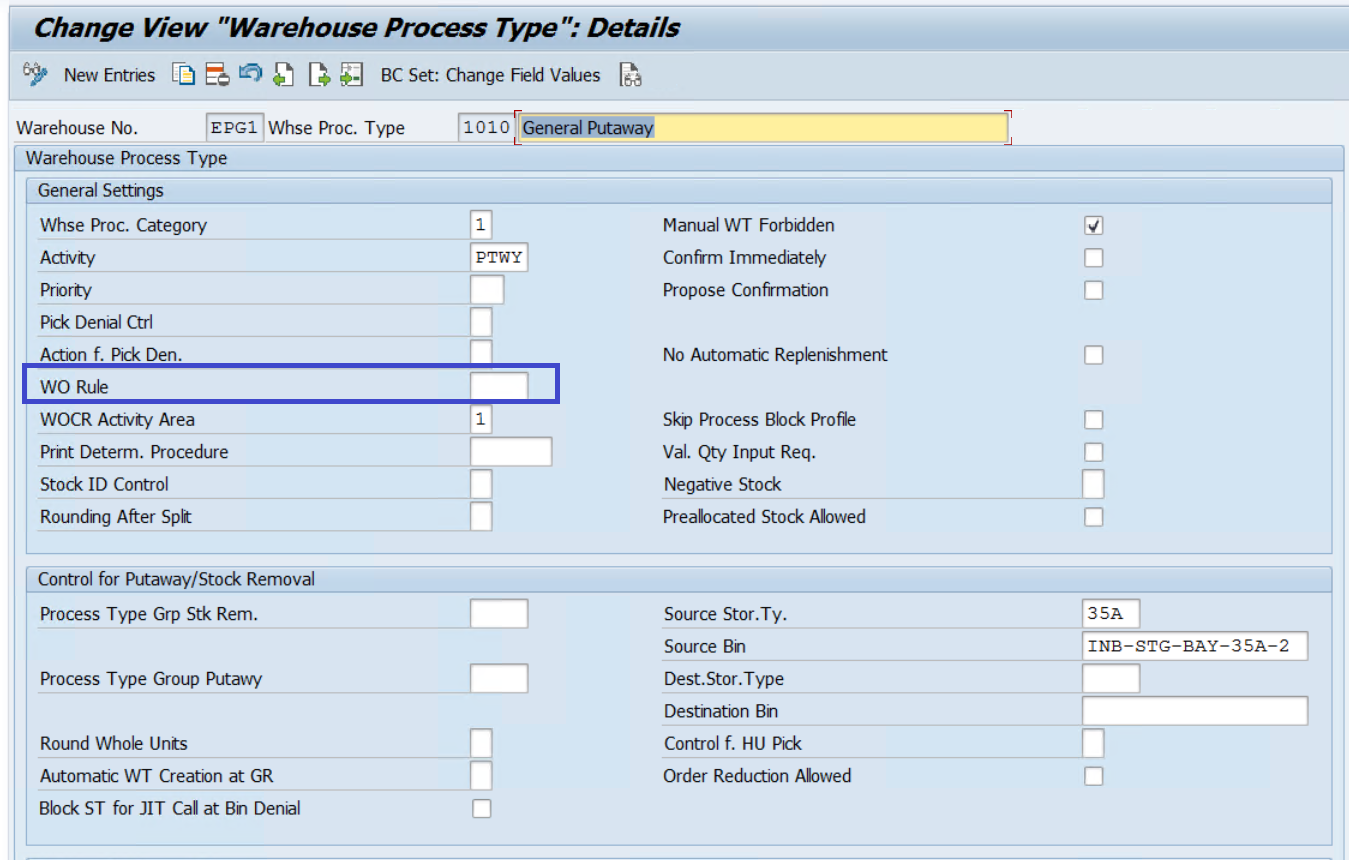

1) Either it is explicitly specified in the Warehouse Process Type (WPT)

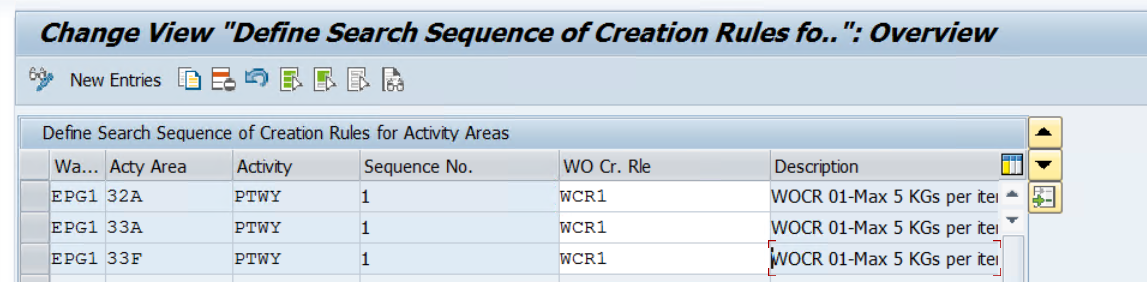

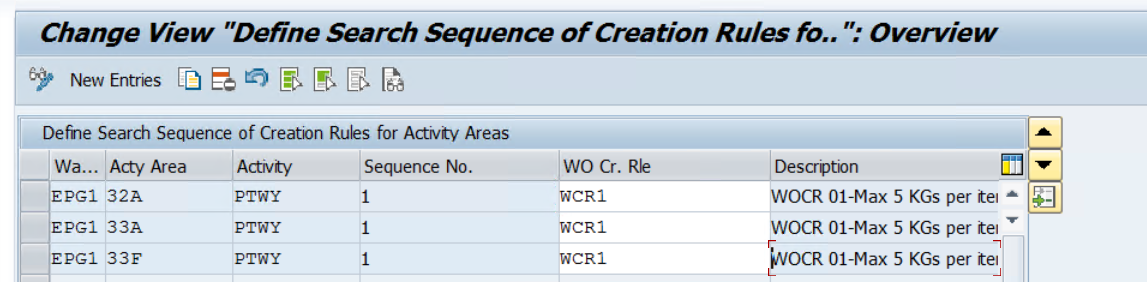

2) It is determined at ‘Define Search Sequence of Creation Rules for Activity areas’

|

EWM FINDS WOCR AT WPT LEVEL (WCR1) |

EWM FINDS WOCR AT ACITIVITY AREA LEVEL (WCR1) |

THE RULE IS SATISIFIED |

FINAL RULE DETERMINED |

|

YES |

NA |

YES |

WCR1 |

|

YES |

NA |

NO |

DEF |

|

NO |

YES |

YES |

WCR1 |

|

NO |

YES |

NO |

UNDE |

|

NO |

NO |

NA |

DEF |

|

IF THE STORAGE TYPE IS RELEVANT FOR MFS (STORAGE TYPE ROLE ‘J’), THE WAREHOUSE TASKS WOULD HAVE THE MFS FIELD ‘KZSUB’ AS X (MFS RELEVANT). IN THIS CASE, THE WOCR DETERMINED WOULD BE MFS. |

|||

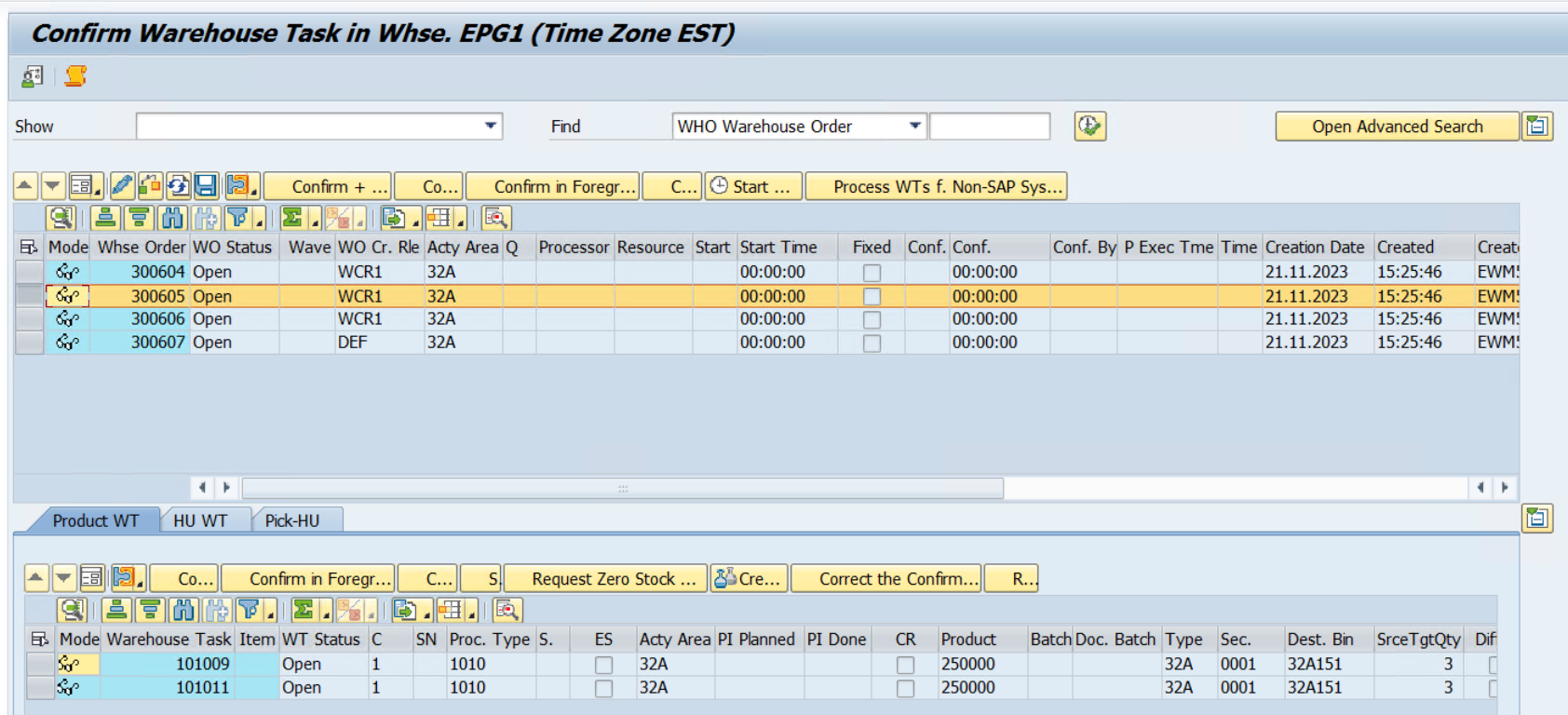

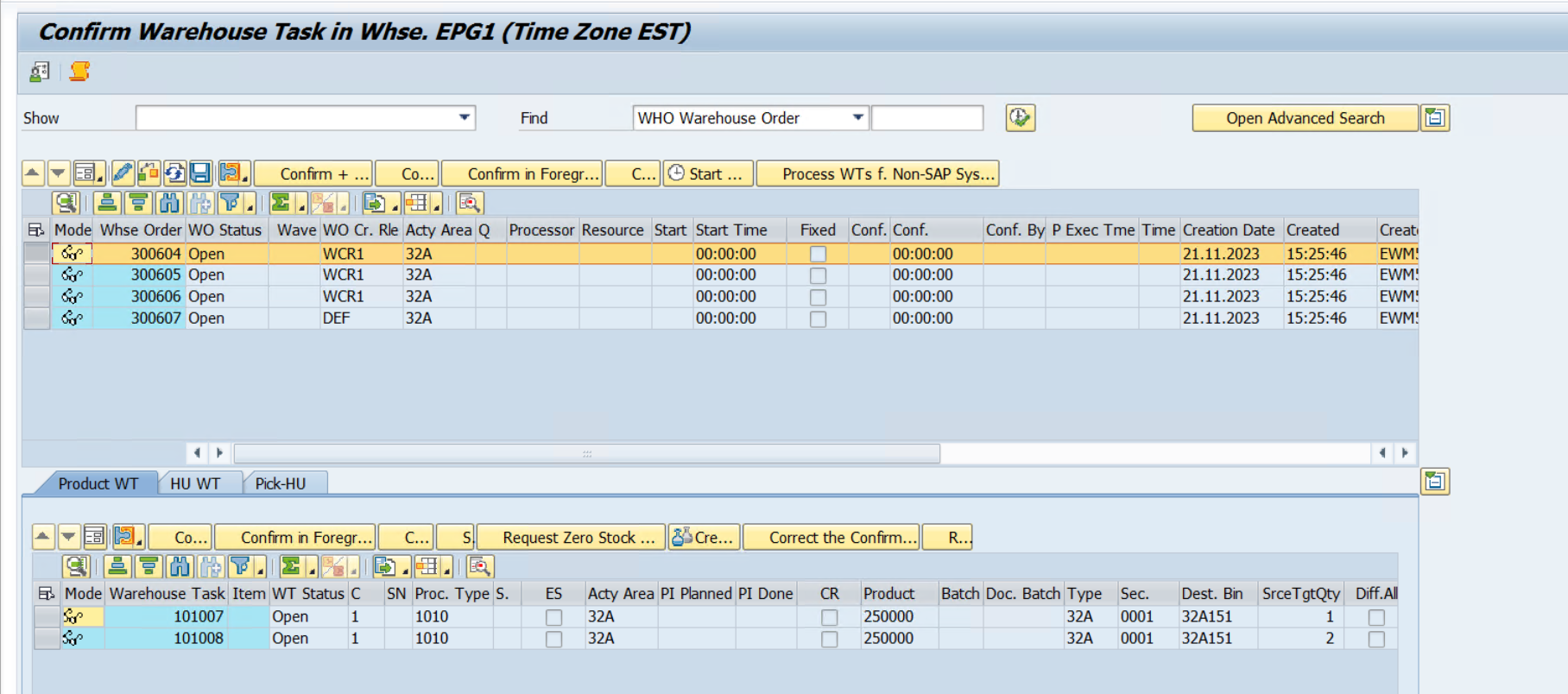

TEST CASES:

-

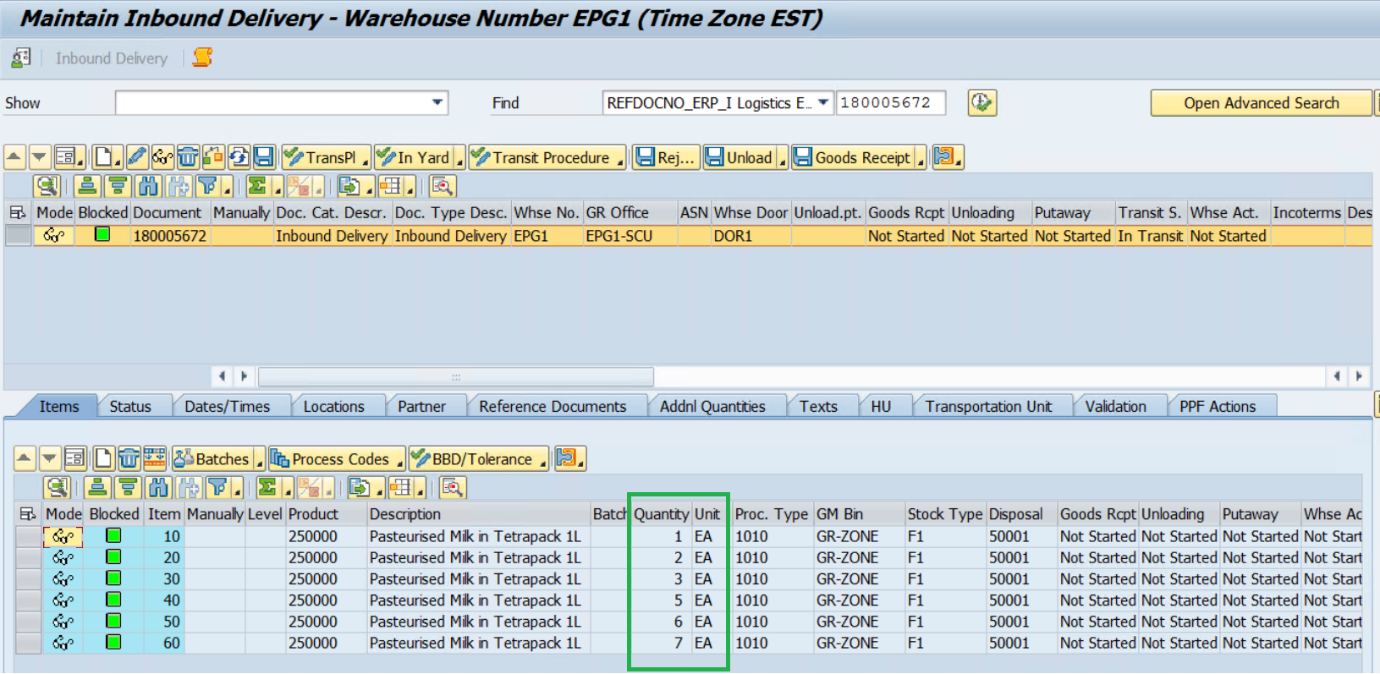

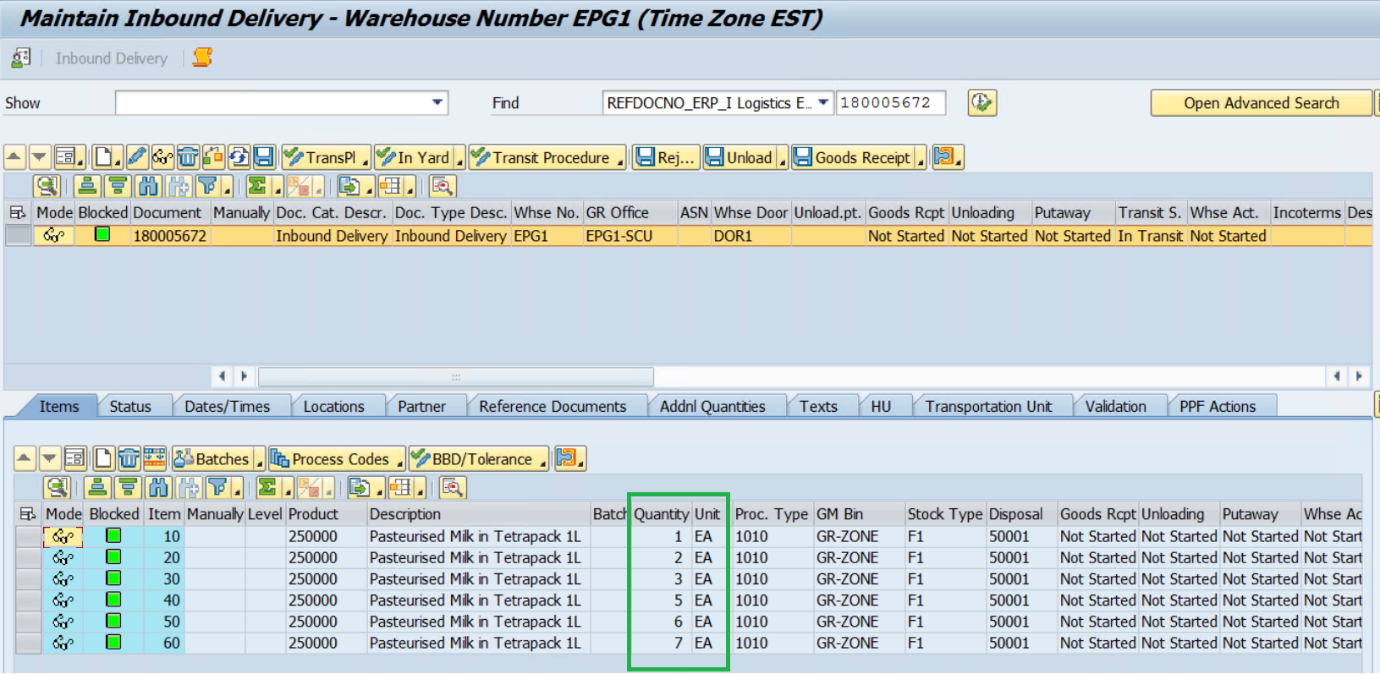

We have 6-line items, with respective quantities shown against each:

-

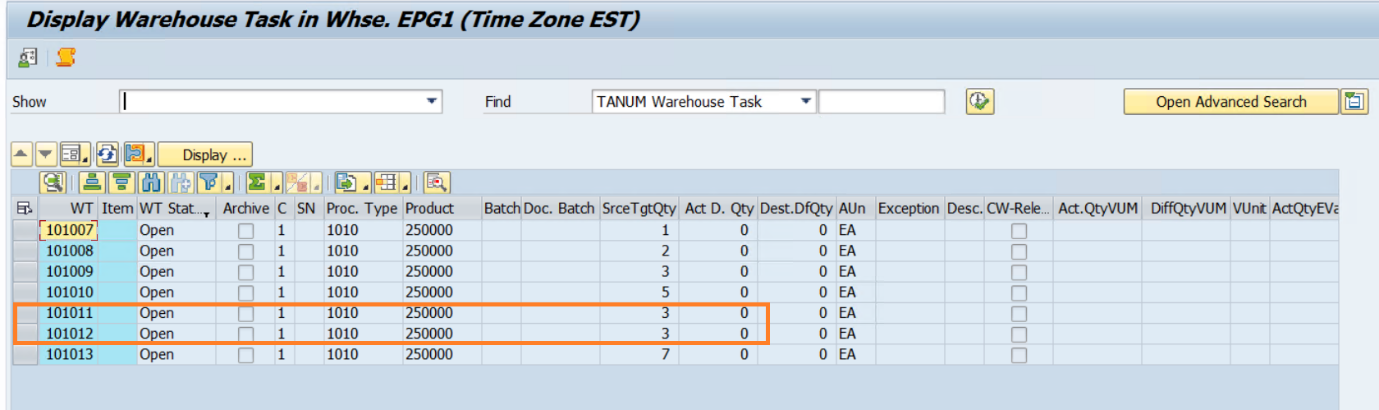

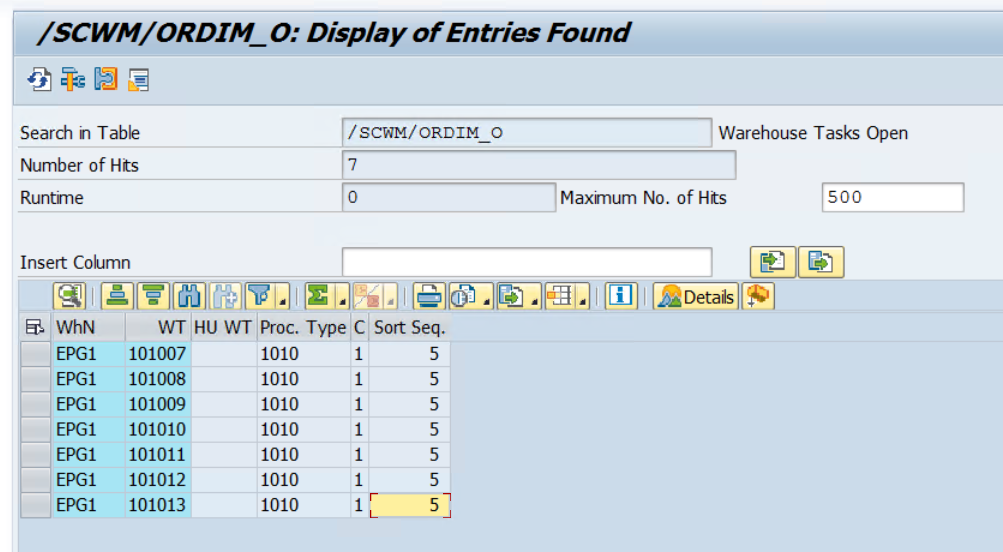

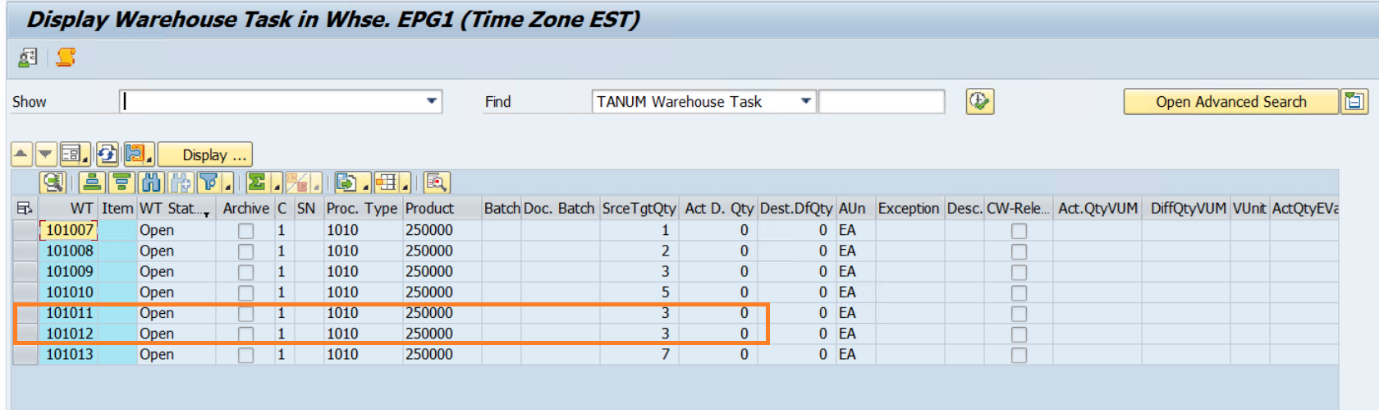

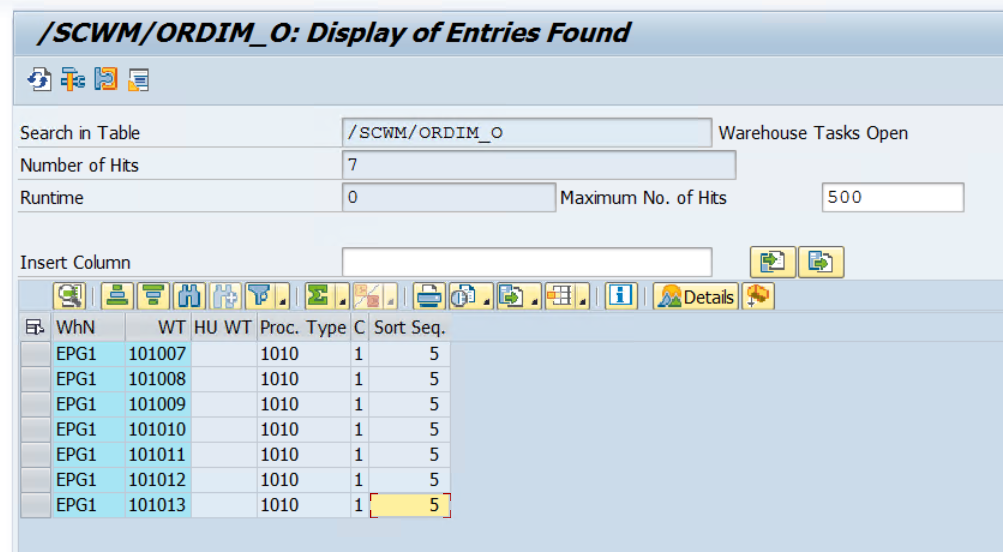

The six-line items are converted in to 7 warehouse tasks (you can ignore why line 50 above is split in two WTs of 3 each, as I am also wondering 😊)

- Since we have now 7 WTs, with weights as below:

|

WT1 – 101007 |

1 KG |

|

WT2 – 101008 |

2 KGs |

|

WT3 – 101009 |

3 KGs |

|

WT4 – 101010 |

5 KGs |

|

WT5 – 101011 |

3 KGs |

|

WT6 – 101012 |

3 KGs |

|

WT7 – 101013 |

7 KGs |

- NOW THE WOCR MACHINE WILL START WORKING TO CONVERT THESE 7 WAREHOUSE TASKS INTO WAREHOUSE ORDERS:

- FIRST A SORT RULE WILL BE APPLIED THAT WOULD ARRANGE THESE WTs in ascending manner:

|

WT1 – 101007 |

1 KG |

|

WT2 – 101008 |

2 KGs |

|

WT3 – 101009 |

3 KGs |

|

WT5 – 101011 |

3 KGs |

|

WT6 – 101012 |

3 KGs |

|

WT7 – 101013 |

7 KGs |

|

WT4 – 101010 |

5 KGs |

- ITEM Filter would flush out the tasks more than 5 KGs, we would be left with below WTs:

|

WT1 – 101007 |

1 KG |

|

WT2 – 101008 |

2 KGs |

|

WT3 – 101009 |

3 KGs |

|

WT5 – 101011 |

3 KGs |

|

WT6 – 101012 |

3 KGs |

|

WT4 – 101010 |

5 KGs |

NOTE: One Correction is in the sequence of above steps 5 and 6. WOCR first applies Item Filters and then SORT Rules.

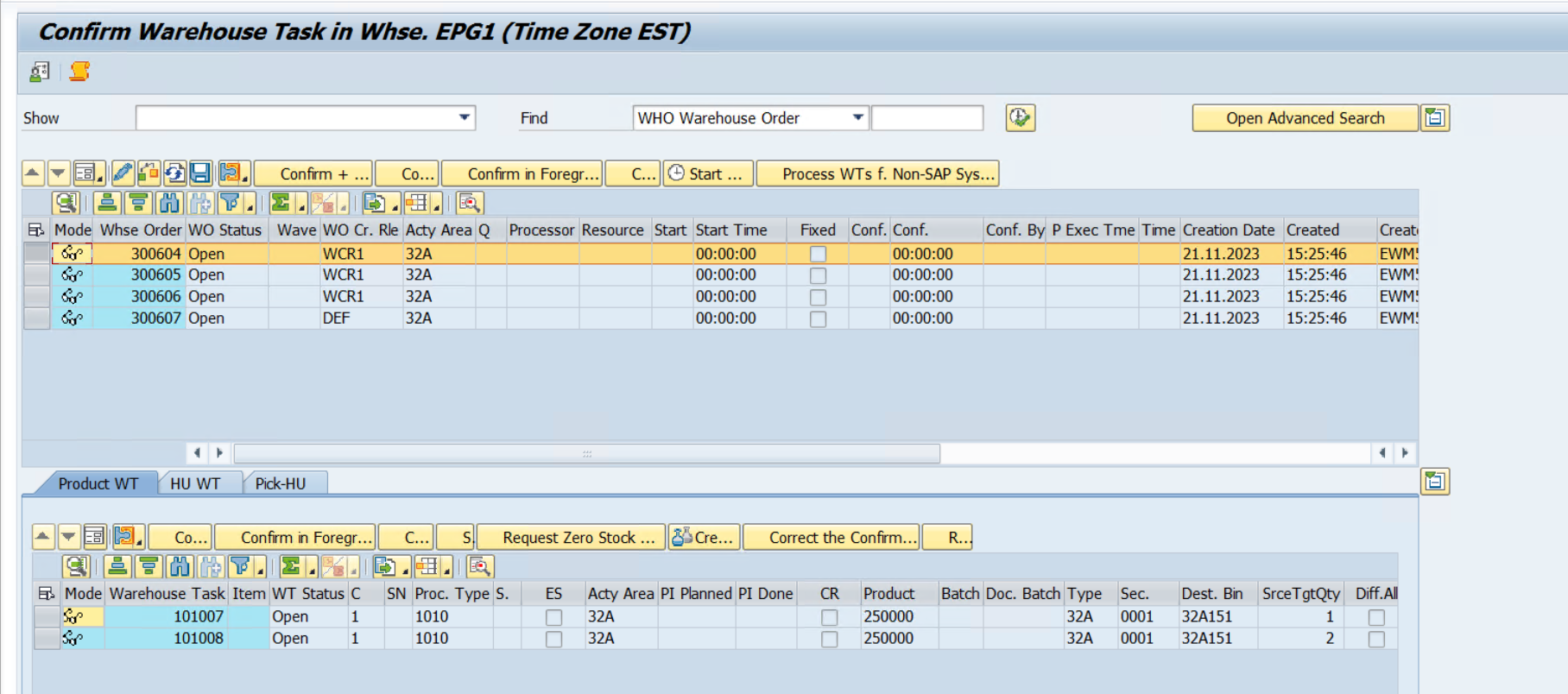

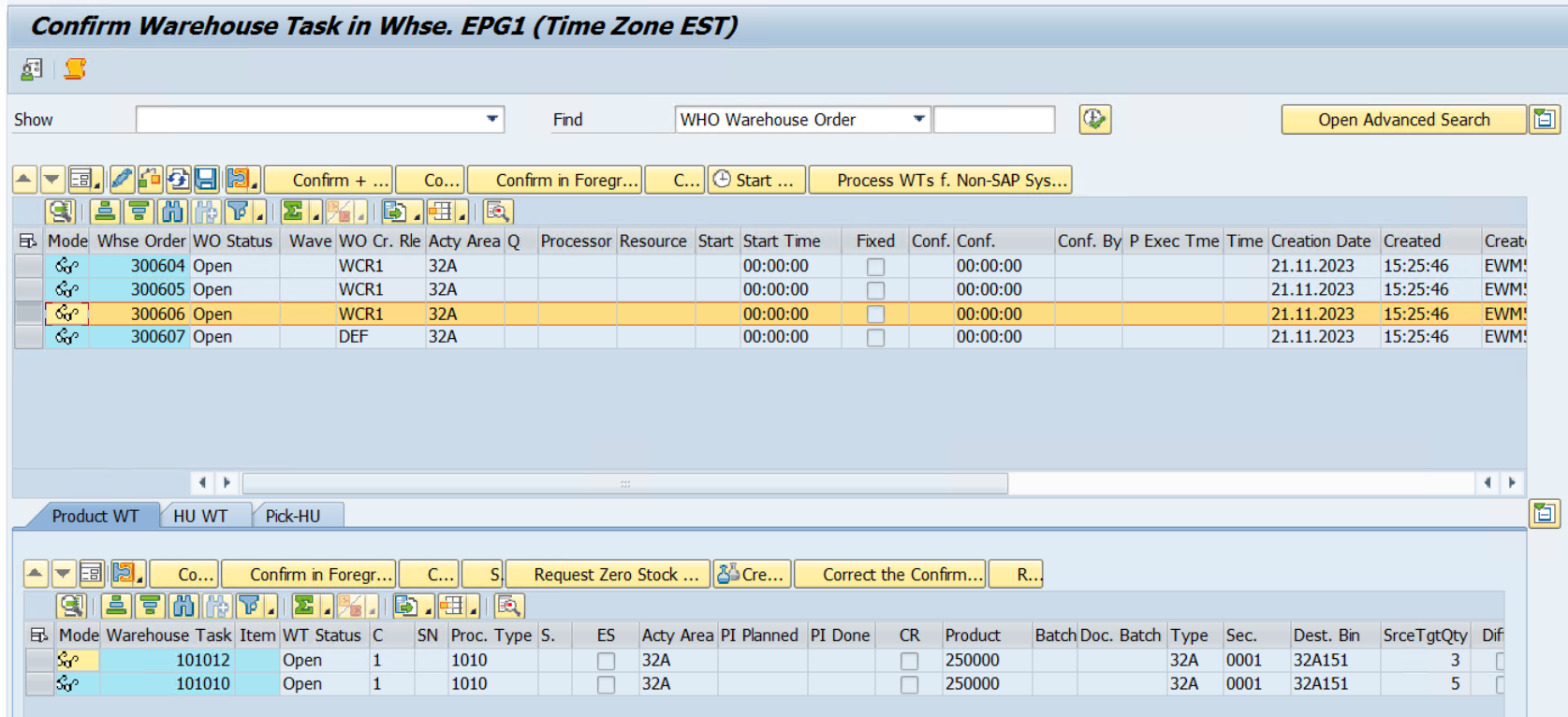

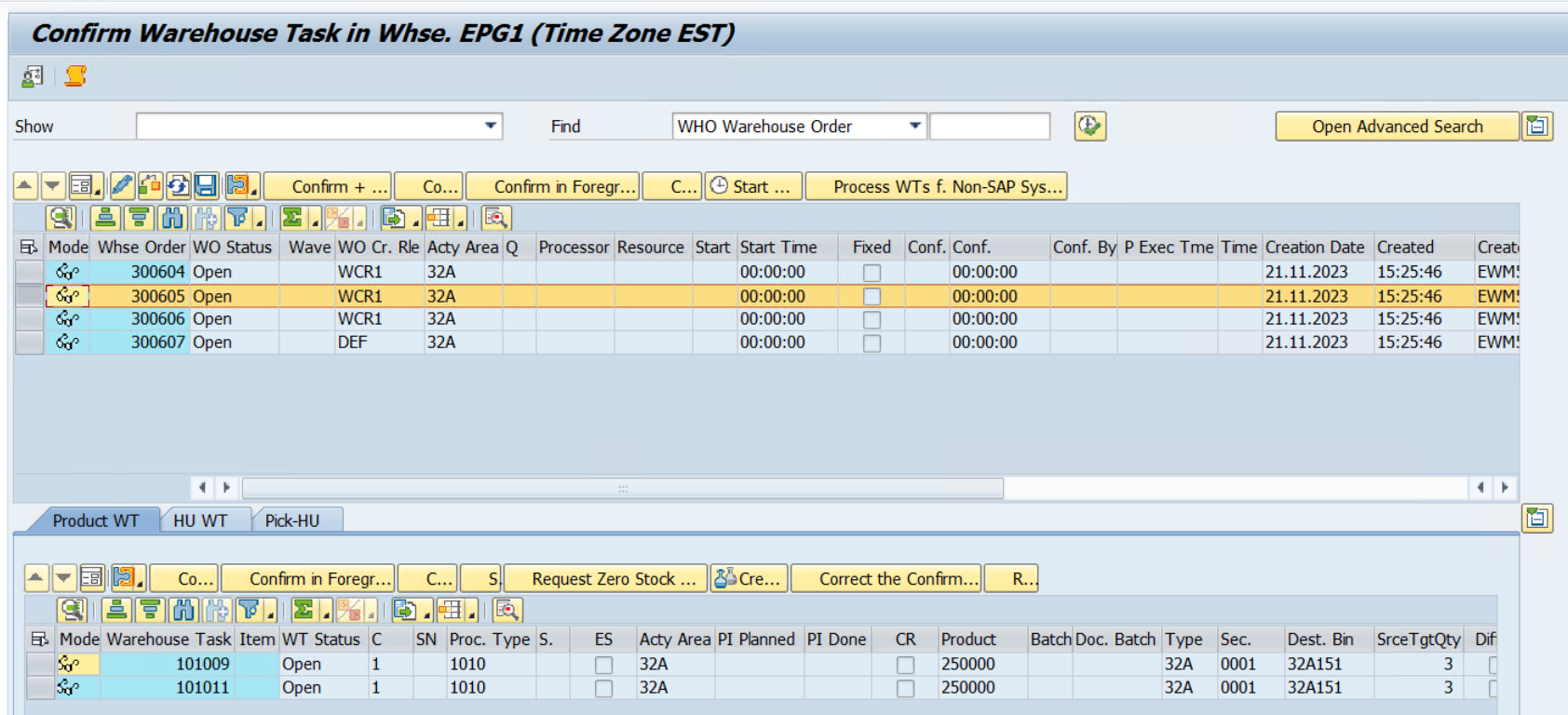

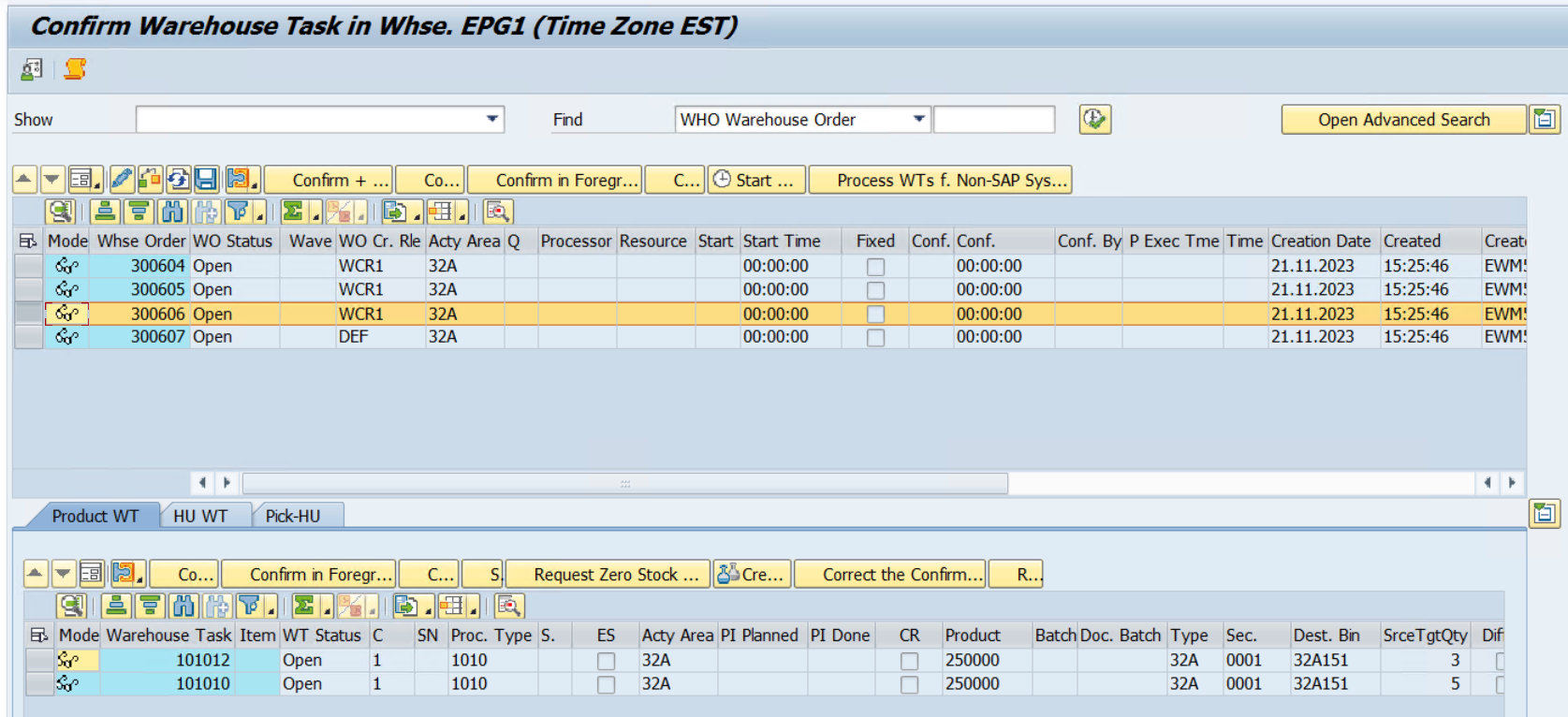

- The Limits would create 3 WO now, since each WO can have a maximum of only 2 WTs:

|

WO1 |

WT1 – 101007 |

1 KG |

|

WT2 – 101008 |

2 KGs |

|

|

WO2 |

WT3 – 101009 |

3 KGs |

|

WT5 – 101011 |

3 KGs |

|

|

WO3 |

WT6 – 101012 |

3 KGs |

|

WT4 – 101010 |

5 KGs |

WO1

WO2

WO2

WO3

WO3

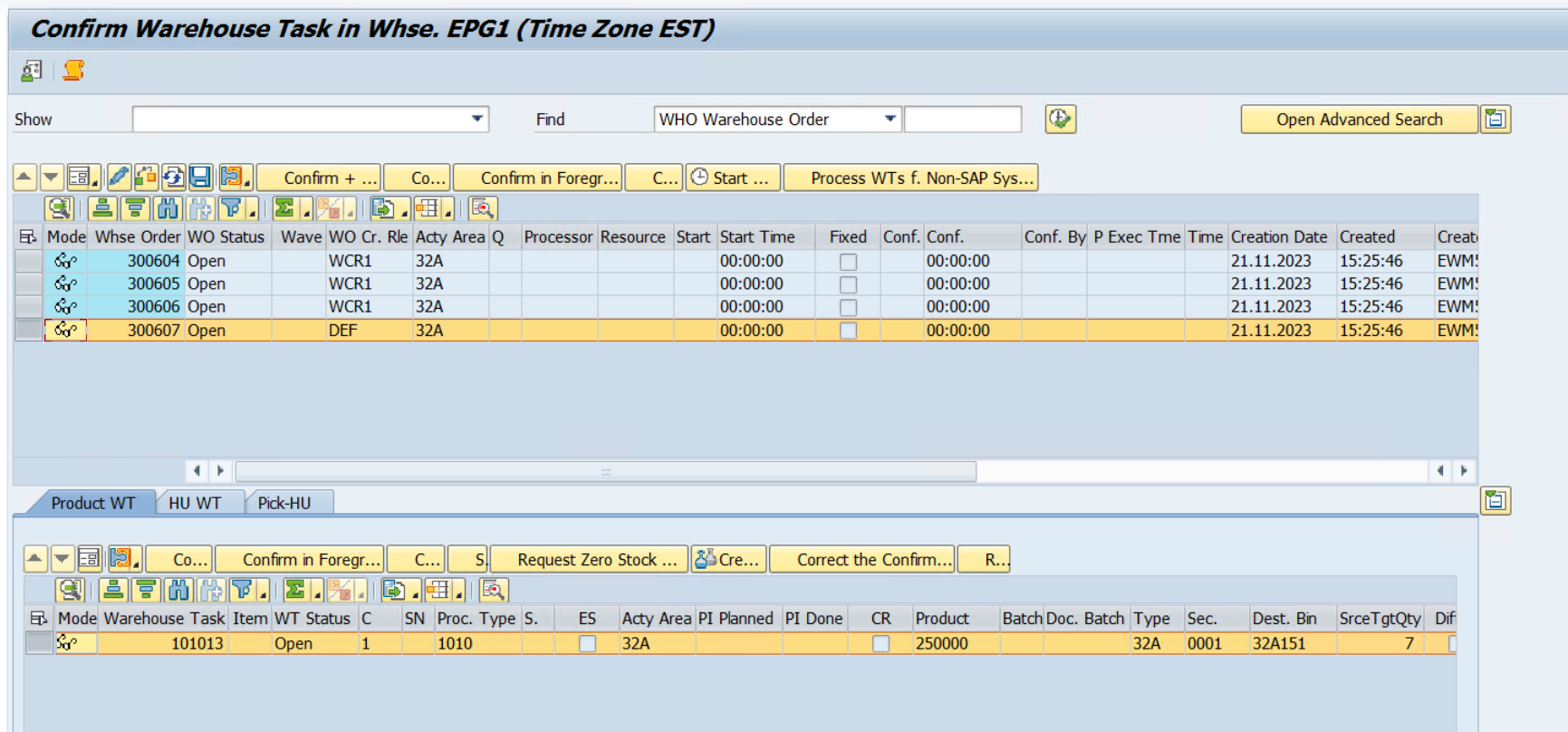

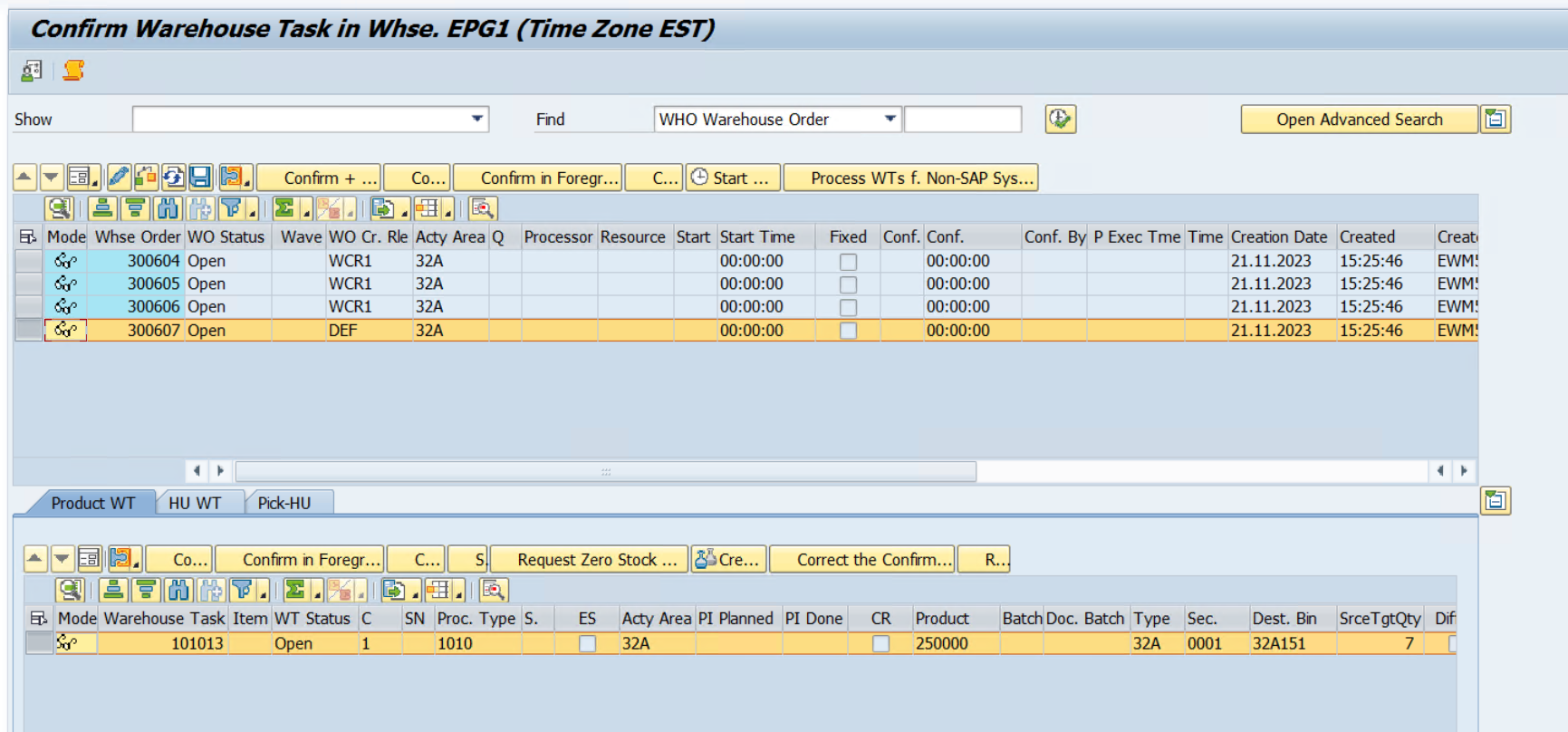

- What will happen to the 7th Warehouse Task – WT7:

|

WT7 – 101013 |

7 KGs |

Since this WT is not able to satisfy the WOCR at WPT level

|

EWM FINDS WOCR AT WPT LEVEL (WCR1) |

EWM FINDS WOCR AT ACITIVITY AREA LEVEL (WCR1) |

THE RULE IS SATISIFIED |

FINAL RULE DETERMINED |

|

YES |

NA |

YES |

WCR1 |

|

YES |

NA |

NO |

DEF |

|

NO |

YES |

YES |

WCR1 |

|

NO |

YES |

NO |

UNDE |

|

NO |

NO |

NA |

DEF |

|

IF THE STORAGE TYPE IS RELEVANT FOR MFS (STORAGE TYPE ROLE ‘J’), THE WAREHOUSE TASKS WOULD HAVE THE MFS FIELD ‘KZSUB’ AS X (MFS RELEVANT). IN THIS CASE, THE WOCR DETERMINED WOULD BE MFS. |

|||

The yellow highlighted line above is satisfied, so the WOCR ‘DEF’ is determined

- What is this DEF Rule?

Ans. It is an in-built SAP EWM Rule named ‘Default’ which ensures that the SORT Rule PIPA is used.

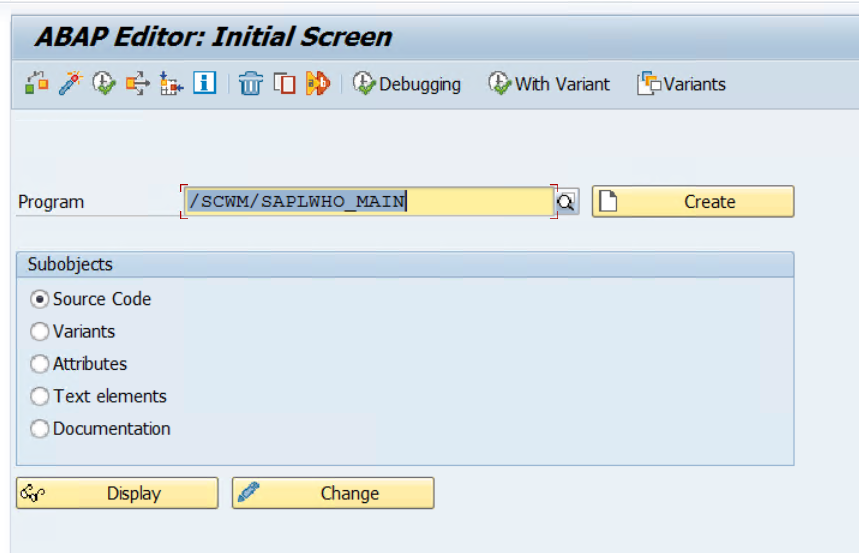

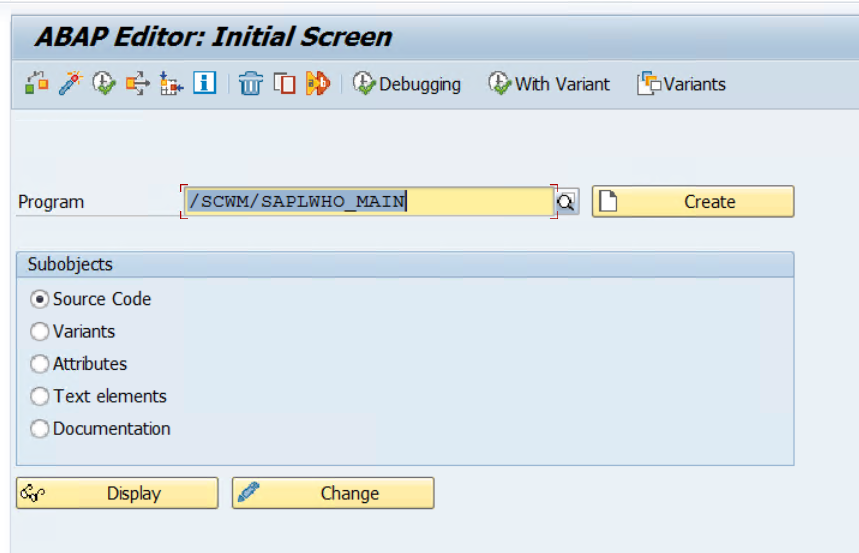

The above Include /SCWM/LWHO_MAINF16 in the program /SCWM/SAPLWHO_MAIN is the place where this Default Rule is getting picked up from.

To explore more, please put a breakpoint in the program before processing the delivery for warehouse task and order creation.

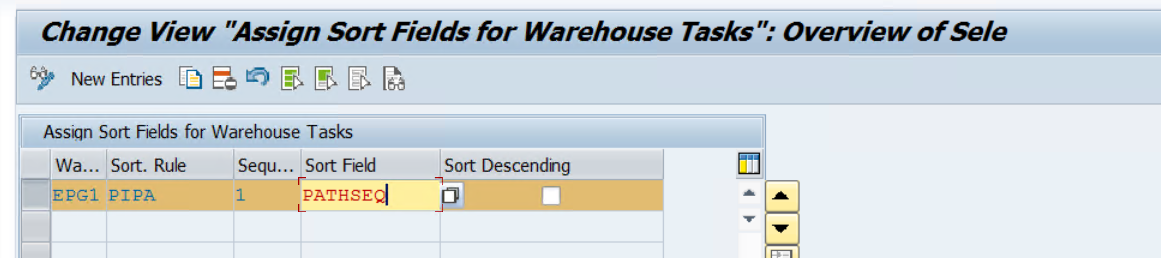

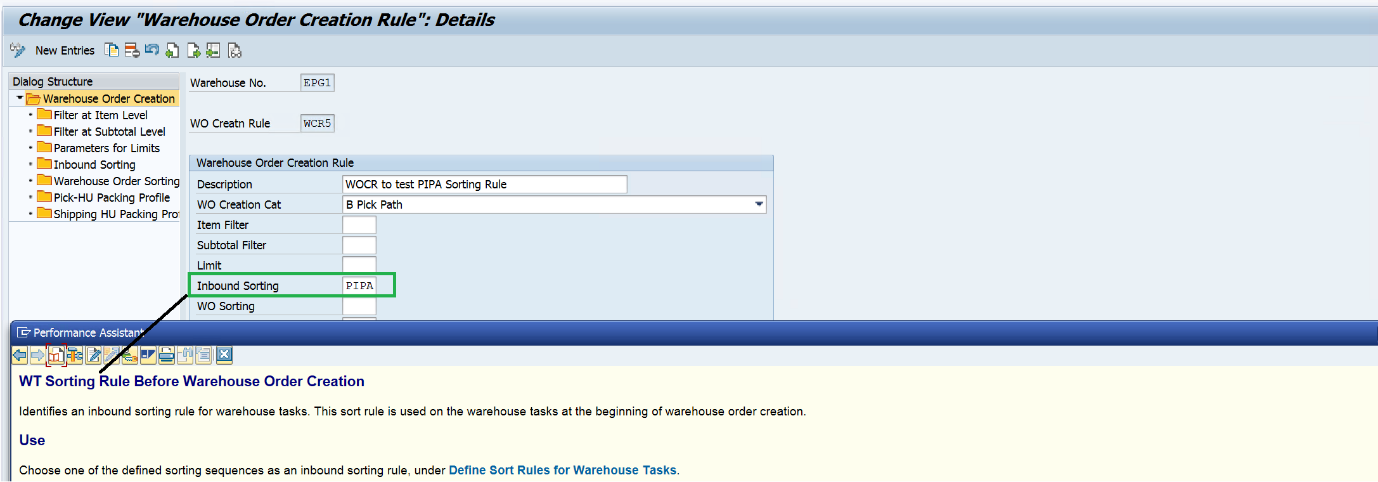

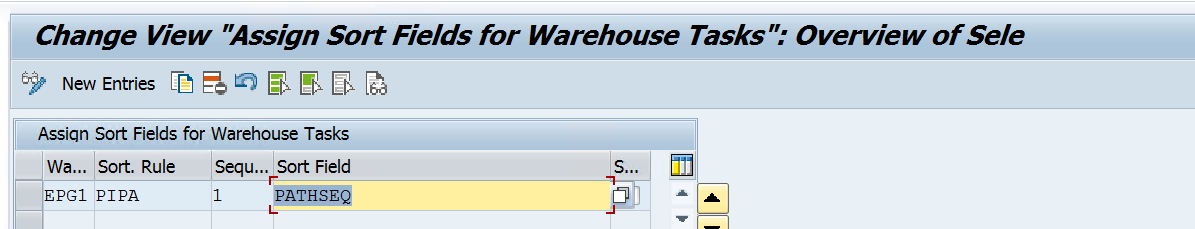

What is SORT Rule PIPA used by DEF and UNDE?

Ans. PIPA is a rule that has the field PATHSEQ assigned to it.

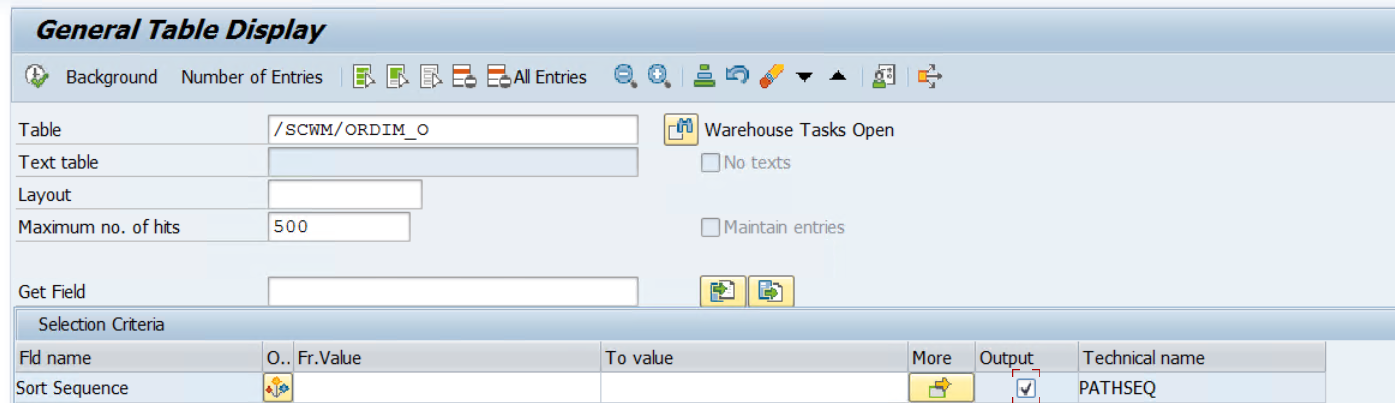

In this example, we cannot see PIPA in action since PATHSEQ is same for all WTs.

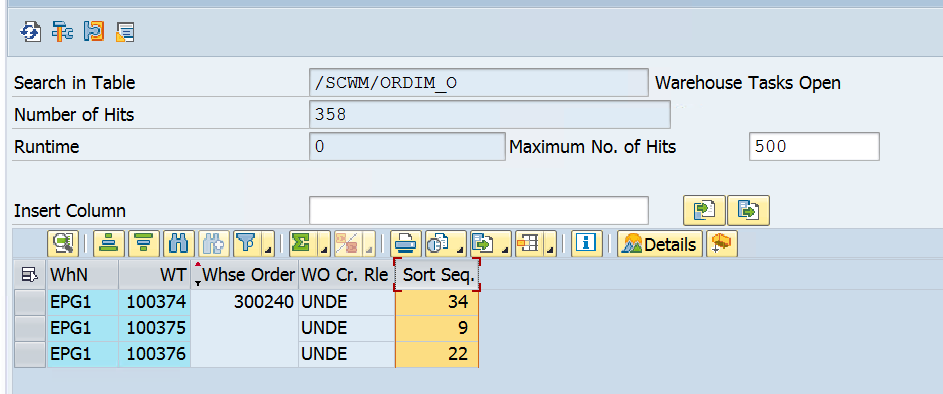

Let’s look at the example below, to see the SORT RULE ‘PATHSEQ’ in Action:

The yellow highlighted field is ‘PATHSEQ’ which is mentioned in the SORT Rule PIPA (in configuration, see below image)

SPRO Path: IMG-SCM EWM-EWM-Cross Process Settings-Warehouse Order-Define Sort Rules for Warehouse Tasks-Define Sort Fields.

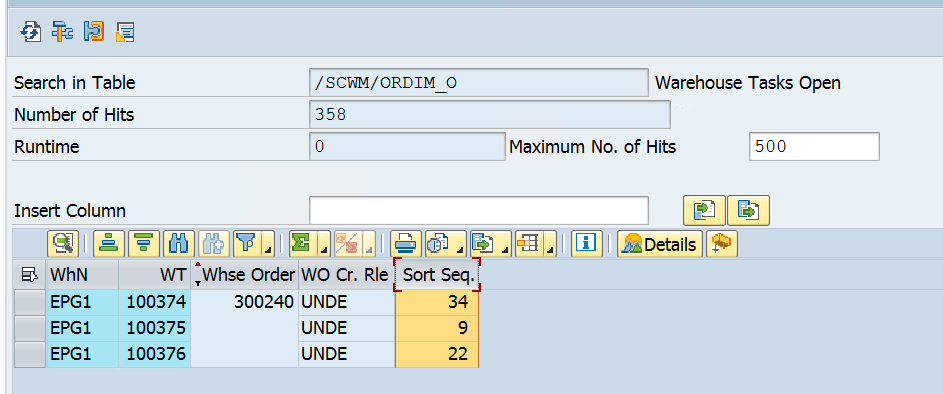

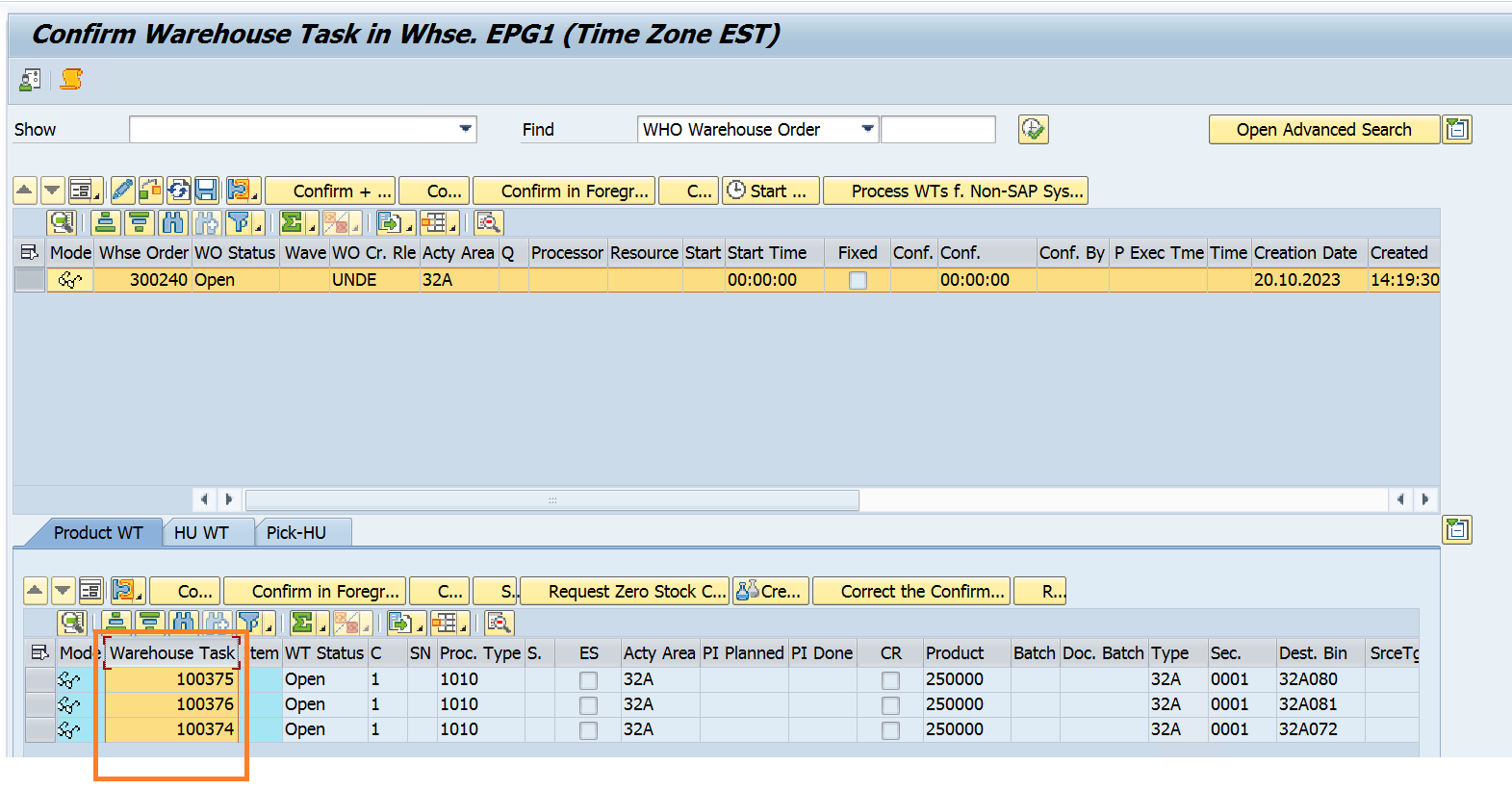

Now, please see below WO and associated 3 WTs in the GUI screen, check the sequence in which warehouse tasks are arranged to be processed:

See, WT 100375 with lowest value of PATHSEQ ‘9’ is shown to be processing as first followed by WT 100376 with next value of PATHSEQ ‘22’ and lastly the WT 100374 with highest value of PATHSEQ ‘34’.

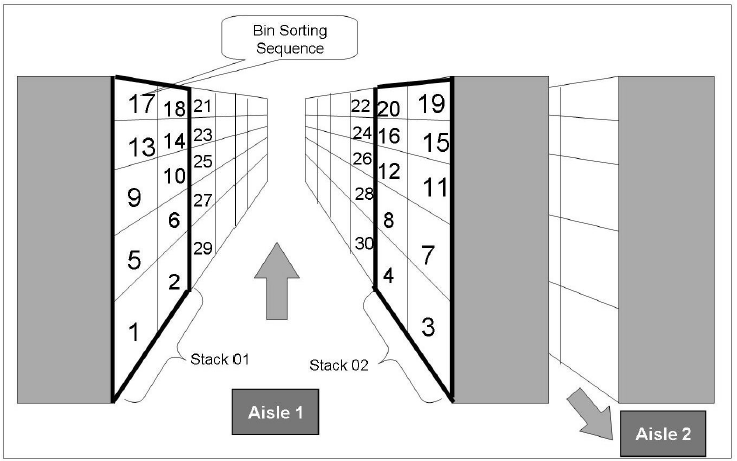

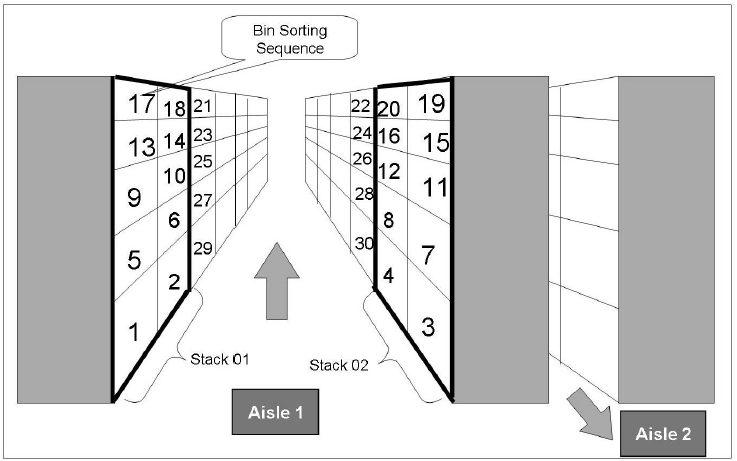

What are these PATHSEQ?

In the above image, the values against each bin are what is being referred to as the SORT Sequence (Technically in SAP, it referred to as the PATHSEQ).

So, to summarize the WOCR’s DEF and UNDE (SAP Defined Warehouse Order Creation Rules) ensure that the Warehouse Tasks are processed by system in the way bins are sorted, from ascending to descending.

How are Bins Sorted?

They can be sorted during initial creation of bins creation using the transaction /n/scwm/sbst. I think this sorting of bins is dynamic and it keeps changing as the transactions are processed, and bins become empty and filled again.

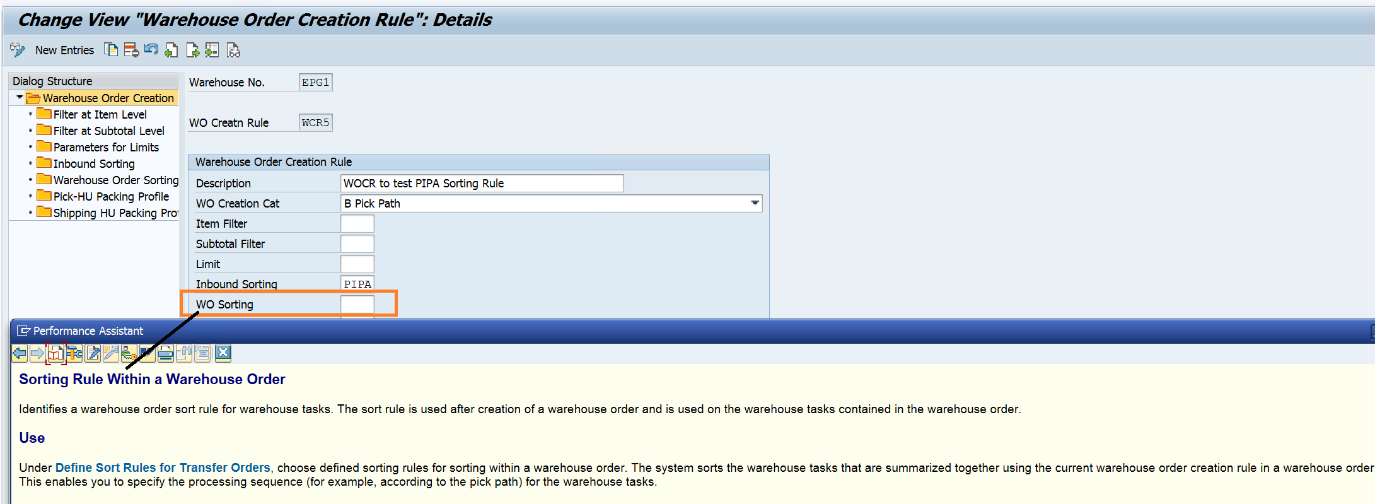

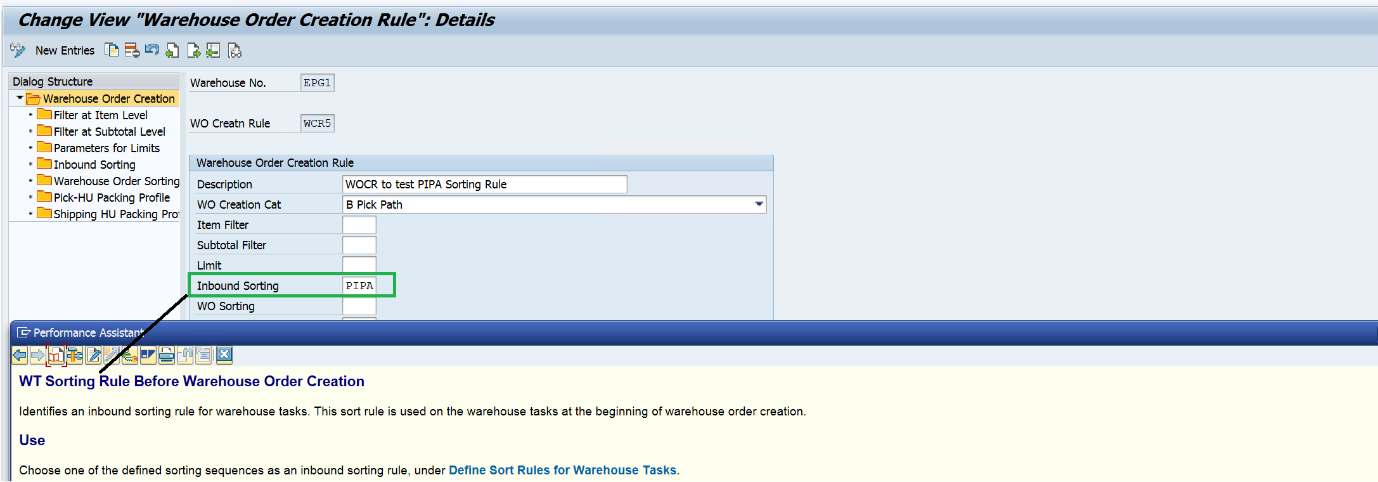

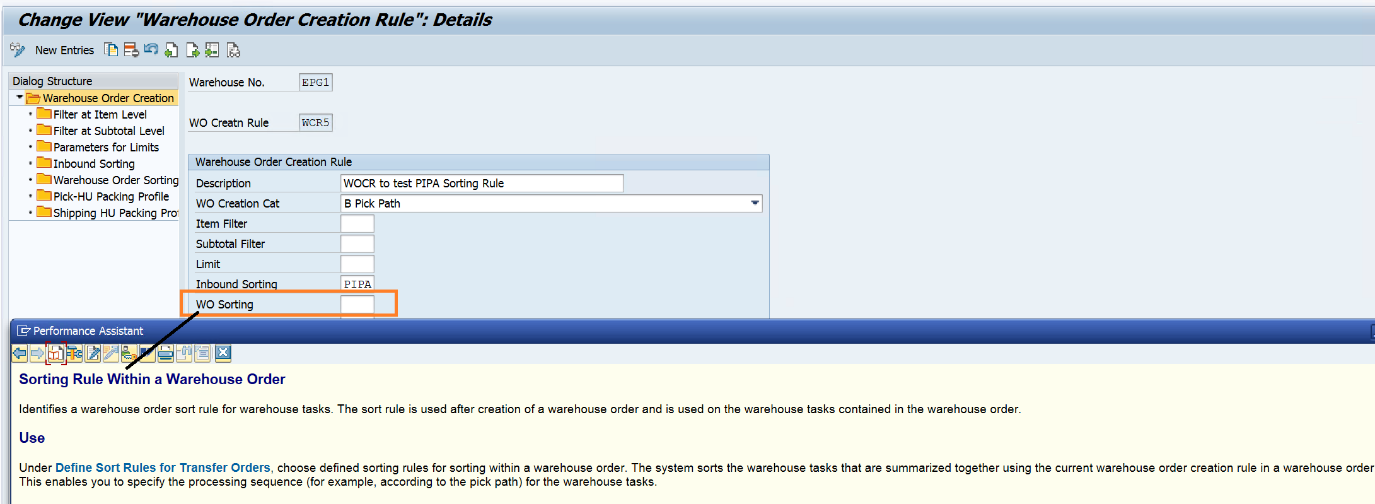

Inbound Sorting Versus WO Sorting (Work in Progress)

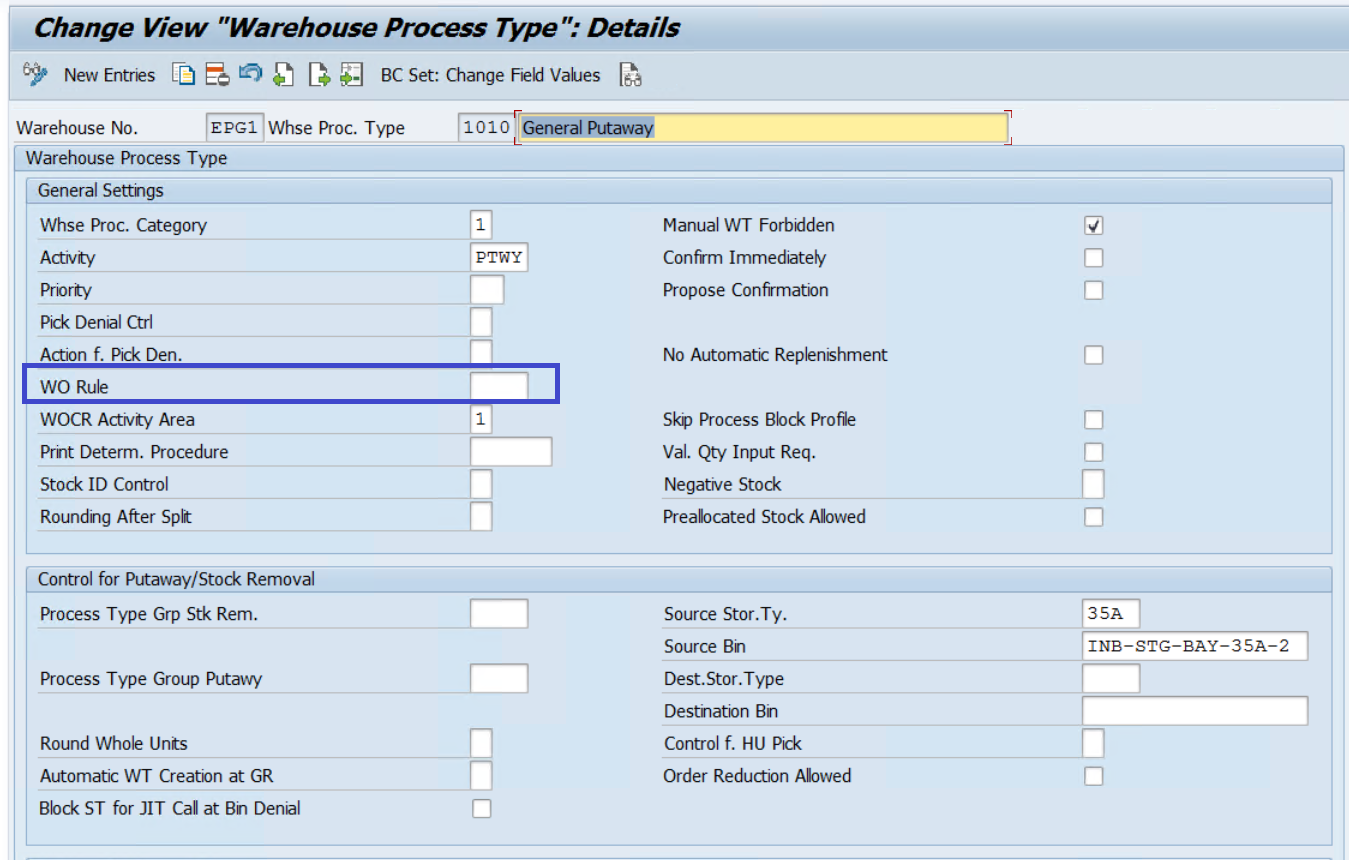

- Now, the example for UNDE where I do not assign the WOCR at WPT but at Activity Area/Activity level:

Before

Now, we delete the highlighted value of WOCR in WPT and maintain the same at Activity Area level:

The WOCR would be now maintained at Activity Area/Activity level:

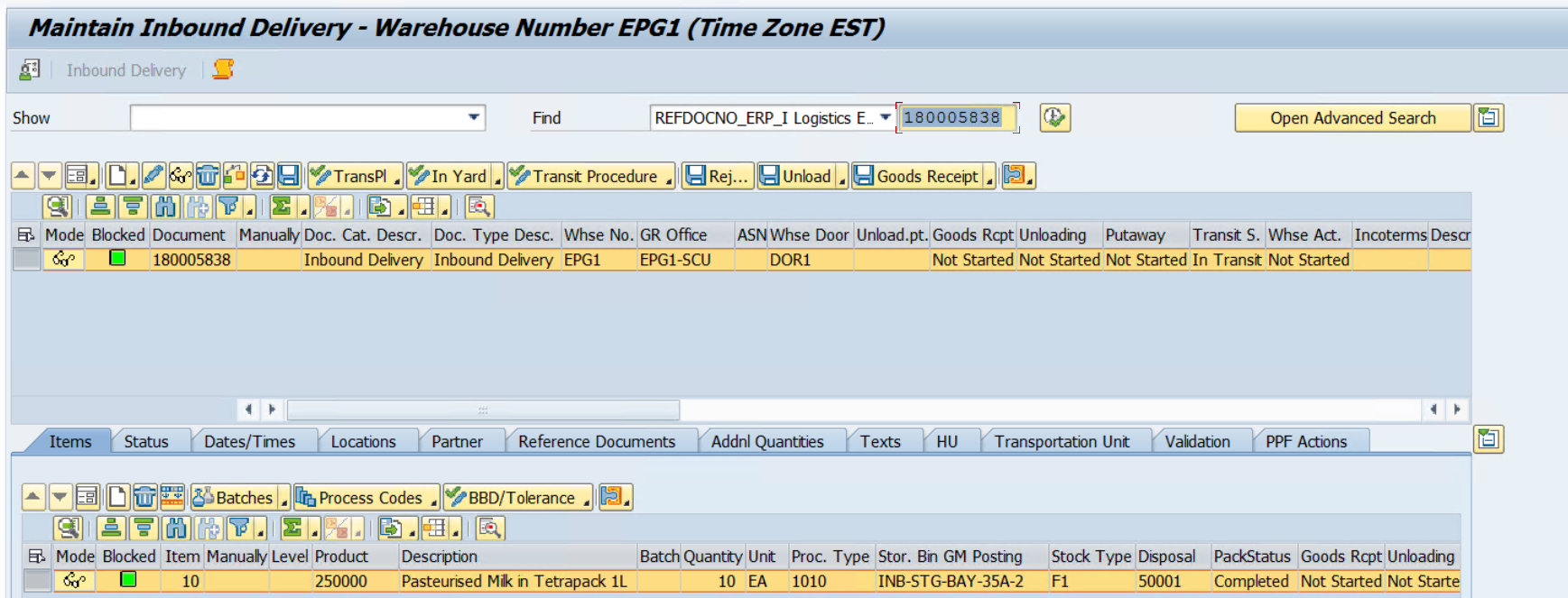

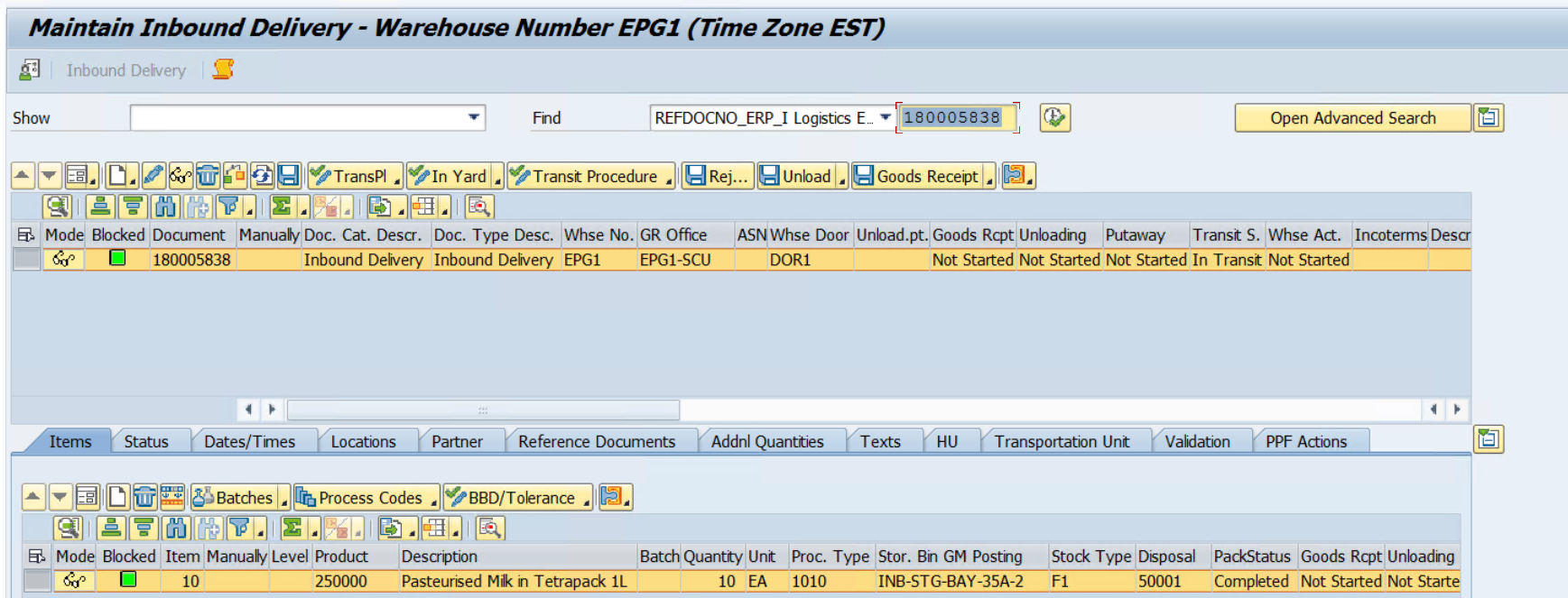

Test Case:

As seen, line item 10 in the EWM delivery has 10EA, which is equal to 10 KGs, now we create the WT for the same:

This is an attempt to understand some aspects of WOCR in SAP EWM, I will try to produce a Video for the same, and share soon.

Lot of things still needs to be explored:

- PIPA/CONS sort rules — PIPA is done now

- Packing Profile/ Packing Profile for Shipping HUs in WOCR — Usage of Packing Profile can be seen in the Pick-HU video on our YT Channel (https://youtu.be/lMsk2lab6sQ?si=-3RjW6nqB12-l1q2)

- Sorting Rule within a warehouse order

- Preparation Time

- CAP compatibility

-

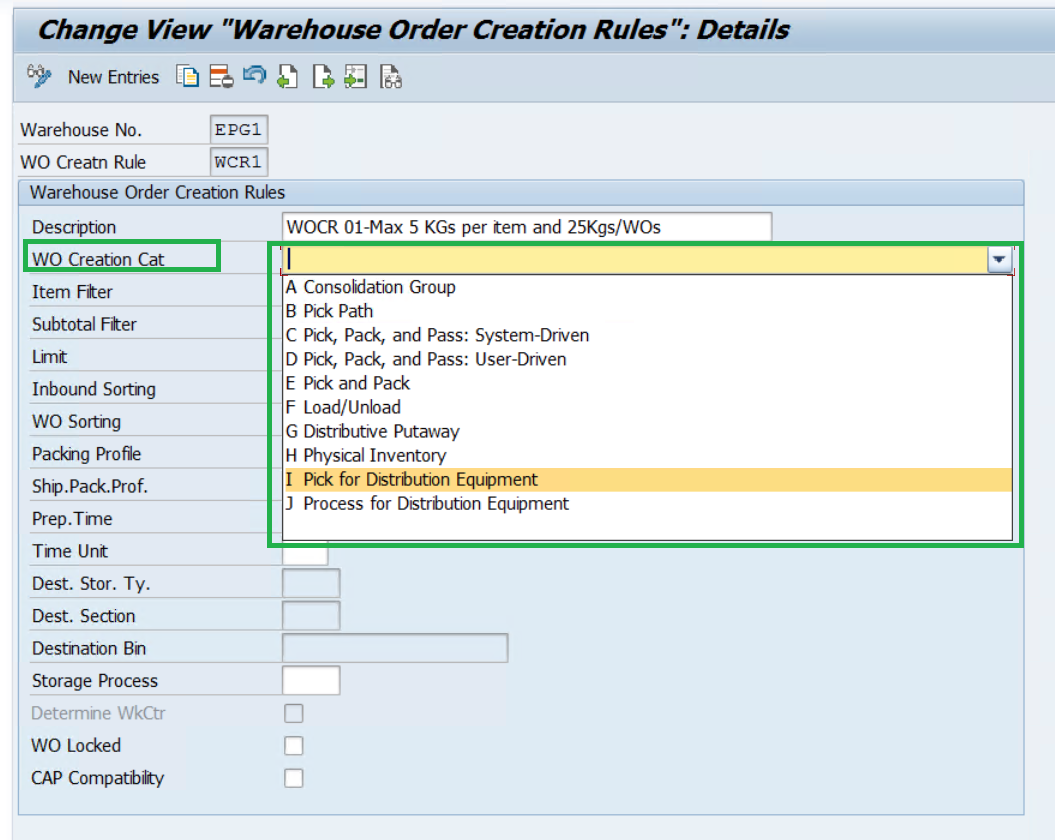

Creation Categories in WO and what’s it is used for

If you would have read till this point, and if you are aware of these pointers above – please help me find answers. Also, you can share custom requirements in your project for the WOCR.

******************************************END************************************

WAREHOUSE ORDER CREATION RULE (WOCR)

Copyright for the above image belongs to SAP Press.

Copyright for the above image belongs to SAP Press.

As the name suggests, it is a Rule to bundle various Warehouse tasks into a Warehouse Order.

This Rule has some criterions listed down below:

SORT RULES LGWT – It has Sort Field WEIGHT (ascending Order)

By default, if the checkbox is not ticked – it means ascending.

ITEM FILTER FIL1 – It has restrictions of filtering WTs less than or equal to 5KGs

LIMIT LIM3 – It will limit the total number of WTs per WO, in our case the same can be less than or equal to 2 WTs per WO.

SAP EWM standard gives 3 WOCRs:

- DEF (Default) – Uses SORT RULE ‘PIPA’ (Field is PATHSEQ in ascending manner)

- UNDE (Undefined) – Uses SORT RULE ‘PIPA’ (Field is PATHSEQ in ascending manner)

- MFS (Material Flow System) – Limits a maximum of one WT per WO, makes sense since these WOs would be operated by machines which are capable of only executing one task at one point of time.

WOCR Determination:

1) Either it is explicitly specified in the Warehouse Process Type (WPT)

2) It is determined at ‘Define Search Sequence of Creation Rules for Activity areas’

|

EWM FINDS WOCR AT WPT LEVEL (WCR1) |

EWM FINDS WOCR AT ACITIVITY AREA LEVEL (WCR1) |

THE RULE IS SATISIFIED |

FINAL RULE DETERMINED |

|

YES |

NA |

YES |

WCR1 |

|

YES |

NA |

NO |

DEF |

|

NO |

YES |

YES |

WCR1 |

|

NO |

YES |

NO |

UNDE |

|

NO |

NO |

NA |

DEF |

|

IF THE STORAGE TYPE IS RELEVANT FOR MFS (STORAGE TYPE ROLE ‘J’), THE WAREHOUSE TASKS WOULD HAVE THE MFS FIELD ‘KZSUB’ AS X (MFS RELEVANT). IN THIS CASE, THE WOCR DETERMINED WOULD BE MFS. |

|||

TEST CASES:

-

We have 6-line items, with respective quantities shown against each:

-

The six-line items are converted in to 7 warehouse tasks (you can ignore why line 50 above is split in two WTs of 3 each, as I am also wondering 😊)

- Since we have now 7 WTs, with weights as below:

|

WT1 – 101007 |

1 KG |

|

WT2 – 101008 |

2 KGs |

|

WT3 – 101009 |

3 KGs |

|

WT4 – 101010 |

5 KGs |

|

WT5 – 101011 |

3 KGs |

|

WT6 – 101012 |

3 KGs |

|

WT7 – 101013 |

7 KGs |

- NOW THE WOCR MACHINE WILL START WORKING TO CONVERT THESE 7 WAREHOUSE TASKS INTO WAREHOUSE ORDERS:

- FIRST A SORT RULE WILL BE APPLIED THAT WOULD ARRANGE THESE WTs in ascending manner:

|

WT1 – 101007 |

1 KG |

|

WT2 – 101008 |

2 KGs |

|

WT3 – 101009 |

3 KGs |

|

WT5 – 101011 |

3 KGs |

|

WT6 – 101012 |

3 KGs |

|

WT7 – 101013 |

7 KGs |

|

WT4 – 101010 |

5 KGs |

- ITEM Filter would flush out the tasks more than 5 KGs, we would be left with below WTs:

|

WT1 – 101007 |

1 KG |

|

WT2 – 101008 |

2 KGs |

|

WT3 – 101009 |

3 KGs |

|

WT5 – 101011 |

3 KGs |

|

WT6 – 101012 |

3 KGs |

|

WT4 – 101010 |

5 KGs |

NOTE: One Correction is in the sequence of above steps 5 and 6. WOCR first applies Item Filters and then SORT Rules.

- The Limits would create 3 WO now, since each WO can have a maximum of only 2 WTs:

|

WO1 |

WT1 – 101007 |

1 KG |

|

WT2 – 101008 |

2 KGs |

|

|

WO2 |

WT3 – 101009 |

3 KGs |

|

WT5 – 101011 |

3 KGs |

|

|

WO3 |

WT6 – 101012 |

3 KGs |

|

WT4 – 101010 |

5 KGs |

WO1

WO2

WO2

WO3

WO3

- What will happen to the 7th Warehouse Task – WT7:

|

WT7 – 101013 |

7 KGs |

Since this WT is not able to satisfy the WOCR at WPT level

|

EWM FINDS WOCR AT WPT LEVEL (WCR1) |

EWM FINDS WOCR AT ACITIVITY AREA LEVEL (WCR1) |

THE RULE IS SATISIFIED |

FINAL RULE DETERMINED |

|

YES |

NA |

YES |

WCR1 |

|

YES |

NA |

NO |

DEF |

|

NO |

YES |

YES |

WCR1 |

|

NO |

YES |

NO |

UNDE |

|

NO |

NO |

NA |

DEF |

|

IF THE STORAGE TYPE IS RELEVANT FOR MFS (STORAGE TYPE ROLE ‘J’), THE WAREHOUSE TASKS WOULD HAVE THE MFS FIELD ‘KZSUB’ AS X (MFS RELEVANT). IN THIS CASE, THE WOCR DETERMINED WOULD BE MFS. |

|||

The yellow highlighted line above is satisfied, so the WOCR ‘DEF’ is determined

- What is this DEF Rule?

Ans. It is an in-built SAP EWM Rule named ‘Default’ which ensures that the SORT Rule PIPA is used.

The above Include /SCWM/LWHO_MAINF16 in the program /SCWM/SAPLWHO_MAIN is the place where this Default Rule is getting picked up from.

To explore more, please put a breakpoint in the program before processing the delivery for warehouse task and order creation.

What is SORT Rule PIPA used by DEF and UNDE?

Ans. PIPA is a rule that has the field PATHSEQ assigned to it.

In this example, we cannot see PIPA in action since PATHSEQ is same for all WTs.

Let’s look at the example below, to see the SORT RULE ‘PATHSEQ’ in Action:

The yellow highlighted field is ‘PATHSEQ’ which is mentioned in the SORT Rule PIPA (in configuration, see below image)

SPRO Path: IMG-SCM EWM-EWM-Cross Process Settings-Warehouse Order-Define Sort Rules for Warehouse Tasks-Define Sort Fields.

Now, please see below WO and associated 3 WTs in the GUI screen, check the sequence in which warehouse tasks are arranged to be processed:

See, WT 100375 with lowest value of PATHSEQ ‘9’ is shown to be processing as first followed by WT 100376 with next value of PATHSEQ ‘22’ and lastly the WT 100374 with highest value of PATHSEQ ‘34’.

What are these PATHSEQ?

In the above image, the values against each bin are what is being referred to as the SORT Sequence (Technically in SAP, it referred to as the PATHSEQ).

So, to summarize the WOCR’s DEF and UNDE (SAP Defined Warehouse Order Creation Rules) ensure that the Warehouse Tasks are processed by system in the way bins are sorted, from ascending to descending.

How are Bins Sorted?

They can be sorted during initial creation of bins creation using the transaction /n/scwm/sbst. I think this sorting of bins is dynamic and it keeps changing as the transactions are processed, and bins become empty and filled again.

Inbound Sorting Versus WO Sorting (Work in Progress)

- Now, the example for UNDE where I do not assign the WOCR at WPT but at Activity Area/Activity level:

Before

Now, we delete the highlighted value of WOCR in WPT and maintain the same at Activity Area level:

The WOCR would be now maintained at Activity Area/Activity level:

Test Case:

As seen, line item 10 in the EWM delivery has 10EA, which is equal to 10 KGs, now we create the WT for the same:

This is an attempt to understand some aspects of WOCR in SAP EWM, I will try to produce a Video for the same, and share soon.

Lot of things still needs to be explored:

- PIPA/CONS sort rules — PIPA is done now

- Packing Profile/ Packing Profile for Shipping HUs in WOCR — Usage of Packing Profile can be seen in the Pick-HU video on our YT Channel (https://youtu.be/lMsk2lab6sQ?si=-3RjW6nqB12-l1q2)

- Sorting Rule within a warehouse order

- Preparation Time

- CAP compatibility

-

Creation Categories in WO and what’s it is used for

If you would have read till this point, and if you are aware of these pointers above – please help me find answers. Also, you can share custom requirements in your project for the WOCR.

******************************************END************************************